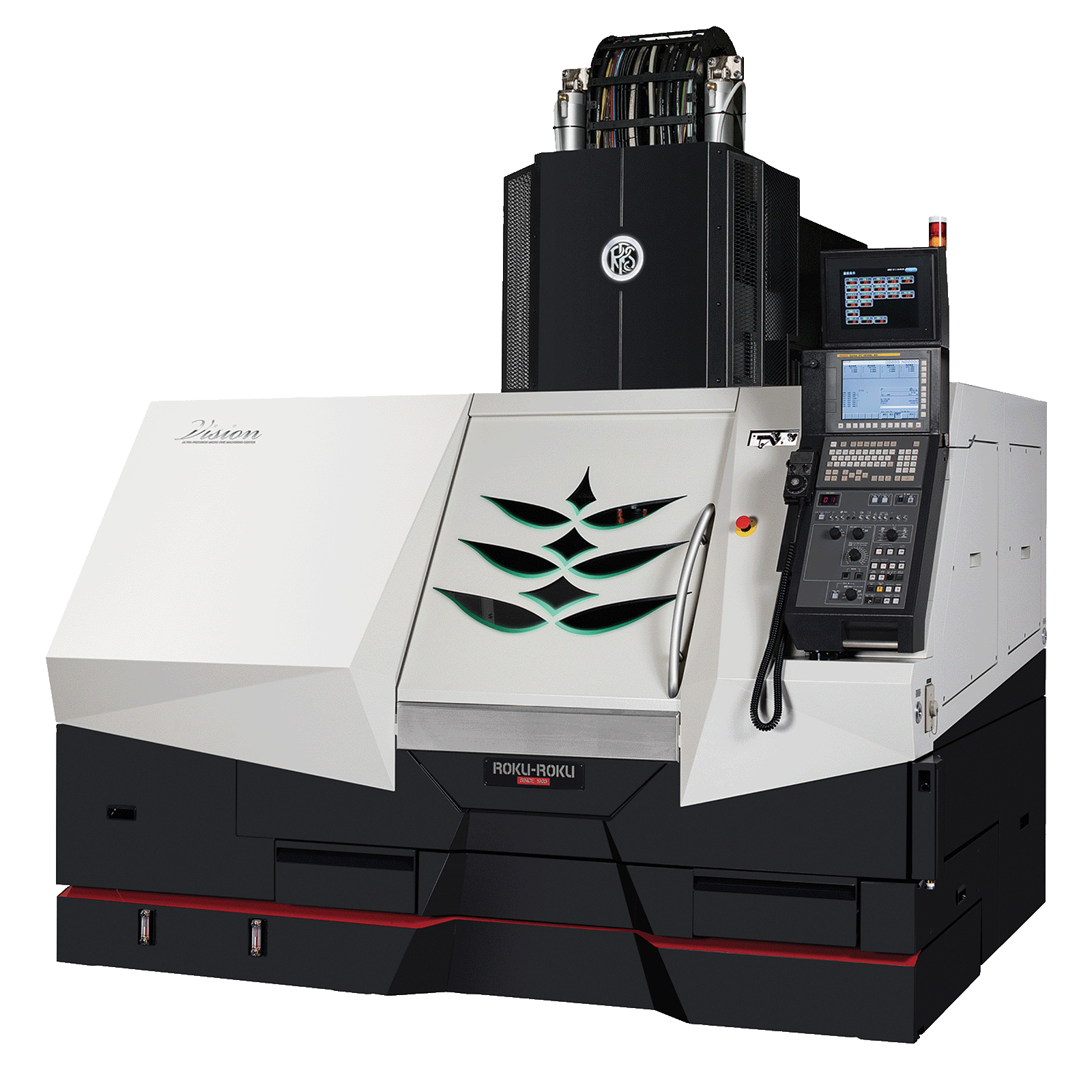

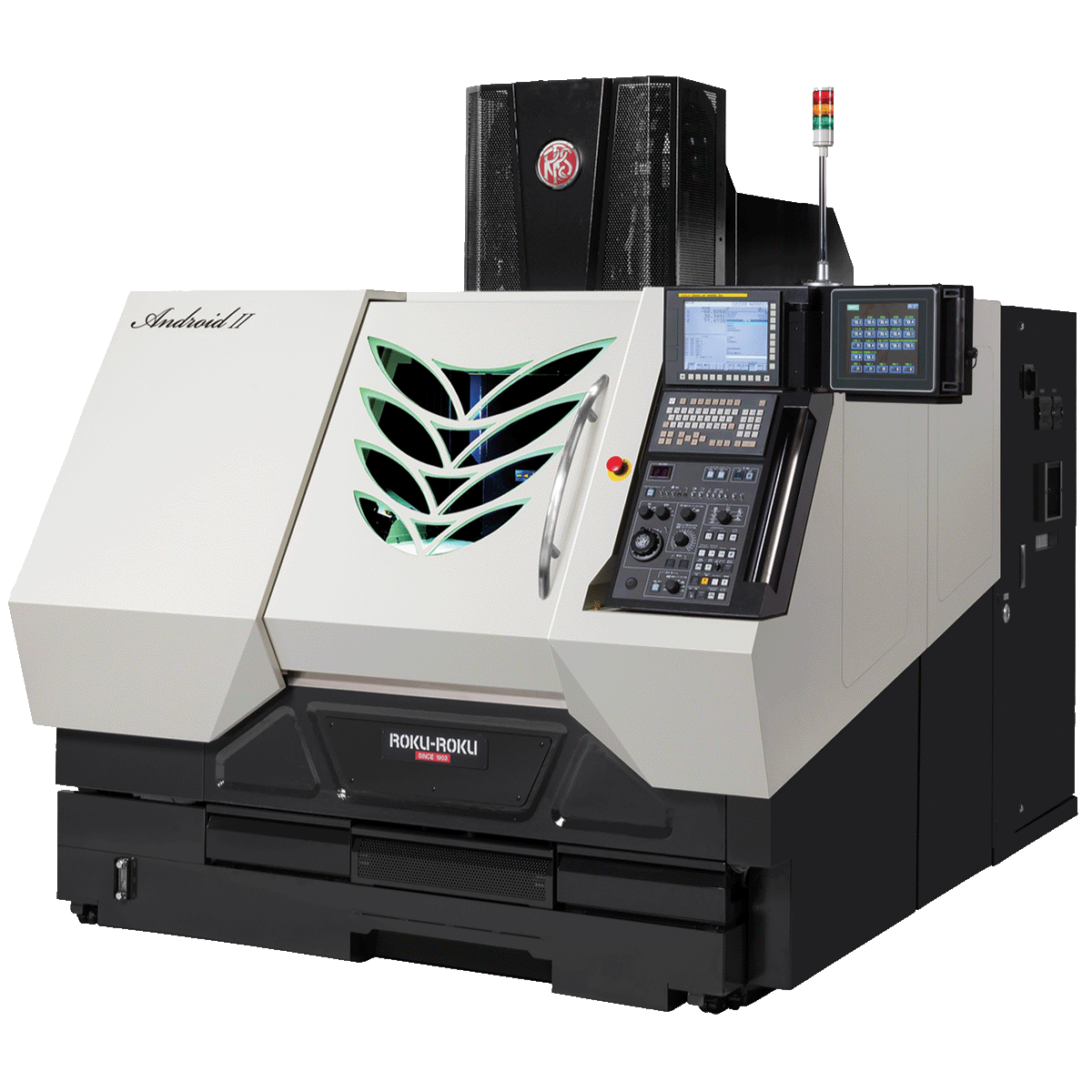

ANDROID II 5AXP-DD

Ultra-Precision Micro Fine 5-Axis Machining Center combined with a flood coolant package for the machining of materials to exacting tolerances.

To boost productivity on high-precision, high-quality jobs, you need a tool that knows how to deliver accuracy, quality, precision, and speed—all at the same time.

The ANDROID II 5AXP-DD is that tool—and then some. It’s a well-built machine that brings together the latest advances in cutting power, working speed, rigid design, heat dispersal, and flexible operation to ensure precise work at high speeds. But with the addition of full 5-axis milling capabilities, with a direct drive tilt/rotary unit, this machine offers results that simply can’t be duplicated.

When your clients require nothing less than perfection, find a machine that can deliver for you—profitably, efficiently, and quickly, over and over again.

CUTTING-EDGE TECHNOLOGY THAT’S NOT JUST FOR SHOW

- The ANDROID II 5AXP-DD has been integrated with a Tsudakoma direct drive 2-axis high-precision table with a 5.9” (150mm) diameter faceplate, turning the ANDROID II into a full 5-axis simultaneous micro-accuracy machining center. And that’s not just for showing off. It’s what makes this machine the best option available for extremely precise, hard-steel machining at high spindle speeds and high traverse rates: true “high-velocity” machining.

TOP-SPEED PRODUCTION CAPABILITIES

- High-speed machining technology has progressed rapidly over the last few years and is ready to take on this task using high-RPM spindles, extremely accurate linear motor servo drive systems, and high-speed machine controllers. The ANDROID II-5AXP-DD is a machining center designed from the ground up for extremely precise, hard-steel machining at high spindle speeds and high traverse rates.

FINE WORK AT ANY SKILL LEVEL

- Coupled with the Fanuc 31i-B5 CNC controller, the ANDROID II is an exceptionally well-built machine tool that can be operated by users of nearly any skill level. With ten (10) preprogrammed machining modes available, your operators can produce great results with unsurpassed speed and accuracy—even in the most complex 3D contours.

RELIABLE BY DESIGN

- The Android II’s heat-symmetric basic frame structure with a high-grade cast iron base ensures twist rigidity against spindle head motion. Its structure guarantees a reduction in thermal displacement, leading to a balance of high rigidity and a reduced weight. The two horizontally opposed, flat linear motors equipped with powerful magnets ensure clearance in the side-ways, canceling out any attraction forces.

- The system’s dual-layer cooling system combines direct forced-oil cooling with a wide-range jacket to separate the spindle head from the casting. Leading to complete heat isolation, the double cooling system positioned between the heat-generating coils is matched by an in-line oil chiller unit to ensure complete control of the coolant temperature. Hot air will never collect at the spindle thanks to the Android II’s centralized exhaust and outside airflow system.

High-speed machining technology has progressed rapidly over the last few years and is ready to take on the task of using high-RPM spindles, extremely accurate linear motor servo drive systems, direct drive rotary axes, high-speed machine controllers, and advanced cutting tool coatings. Roku-Roku, a specialty machine tool builder known for making high-quality, extremely accurate machines, has researched and incorporated all of these technologies into the ANDROID II 5AXP-DD model. The ANDROID II 5AXP-DD is a machining center designed from the ground up for extremely precise, hard-steel machining at high spindle speeds and high traverse rates: true “high-velocity” machining.

The Roku-Roku ANDROID II 5AXP-DD is an exceptionally well-built machine tool coupled with the Fanuc 31i-B5 CNC controller. Roku-Roku’s Super PC III optimizes velocity and acceleration/deceleration through the use of a super high-speed processor and AI Contour Control II, high-speed processing, Nano smoothing, and look-ahead block expansion. The combination of high-speed calculation and read-ahead control minimizes geometric errors during high-speed contouring of continuous small motion commands. Super PC III can be set to one of three different modes to meet your machining requirements. The Roku-Roku ANDROID II 5AXP-DD also features Fanuc’s Digital Intelligent Servo System with five-decimal-place input and feedback. This combination results in unsurpassed speed and accuracy, even in the most complex 3D contours consisting of short, consecutive line segments or arcs.

The Roku-Roku ANDROID II 5AXP-DD is designed around a thermally symmetrical frame. The casting/frame maintains its machine posture against environmental change in temperature. A symmetrical frame is required for stable repeatability. The optimum structure is implemented by finite element analysis for casting parts. Minimum displacement is implemented by structural CAD simulation analysis. The rib structure for cross rail with micro-fine machining center design has a three-layer hollow structure that is efficiently achieved with forced ventilation.

The ANDROID II 5AXP-DD uses a 60,000-RPM spindle. Without sufficient spindle RPM, it would be impossible to machine hardened steel efficiently. High RPM enables an operator to maintain chip load and depth of cut while increasing feed rate. The result is a larger volume of stock removal in less time than conventional machining methods. This method of machining also produces superior surface finishes, resulting in less polishing time. It is a proven method of machining that increases productivity in all aspects of machining (i.e., surface milling, side milling, drilling, etc.).

The Roku-Roku ANDROID II 5AXP-DD uses a pair of horizontally opposed linear drive motors mounted in each of the X-, Y-, and Z-axis. This design offsets the magnetic force between the motors and minimizes the uneven load on the guides and moving parts a single linear motor creates. Double cooling channels are incorporated to ensure that any coil-generated heat does not affect machining accuracy. Special precision roller-type linear motion ways are used on all axes, increasing the contact point by 6 times compared to ball-type LM guides. This increased contact area improves machine rigidity, providing smooth motion for high-precision accuracy. Elongation of the carriage and expanding the supporting width of the casting have also improved the straightness of the cut. An active heat isolation system has been implemented on the ANDROID II 5AXP-DD, providing full thermal control of the machine in accordance with room temperature. The system provides coolant thermal control through double-jacketing the spindle housing with a spindle oil cooler and cooling through the Z-axis casting. Other heat sources such as the linear motor coils and control cabinet have been heat isolated and thermally controlled by chiller coolant or forced-air circulation.

The ANDROID II 5AXP-DD has been integrated with a Tsudakoma direct drive 2-axis high-precision table with a 5.9” (150mm) diameter faceplate, turning the ANDROID II into a full 5-axis simultaneous micro-accuracy machining center. The Fanuc control has the NC option package for 5-axis machining for full 5-axis program operation.

COMPONENTS:

- X, Y, and Z axis linear motor drive system

- Z-axis thermal growth compensation

- Special precision roller-type linear motion ways

- Full enclosure design

- Special way covers to reduce motion resistance

- 60,000-RPM integral motor spindle

- Spindle chiller

- Non-contact tool measurement (Blum laser) with air blow

- Tsudakoma direct drive (RRT-216AA) 2-axis rotary table

- 53-gallon (200L) coolant tank

- 20-position automatic tool changer

- X, Y, and Z axis (2 nanometer) linear scales

- Tool tightening block

- Automatic power shutdown circuit

- Work washer gun

- Air purge

- 10.4” color monitor

- 2-stage patrol lamp (yellow, red)

- Manual handle feed

- One machine lamp (LED)

- Toolbox

- Maintenance kit

- Leveling bolts and pads

ON-BOARD AUTOMATION:

- Automatic lubrication system

USER INTERFACE:

Fanuc 31i-B5 control features:

- Super PC X + Function (10-mode operation)

- AI Contour Control II, high-speed processing, Nano smoothing, and look-ahead block expansion

- Editable data server with 2GB program storage (flash card type)

- Ethernet with TCP/IP protocol & RS232 communications

- 320-meter memory (128KB)

- 160-meter memory (64KB)

- Custom macro B

- Parts count & run hour display

- Helical interpolation

ADDITIONAL BENEFITS:

- remote360°-enabled (remote user monitoring, diagnostics, service support, and more)

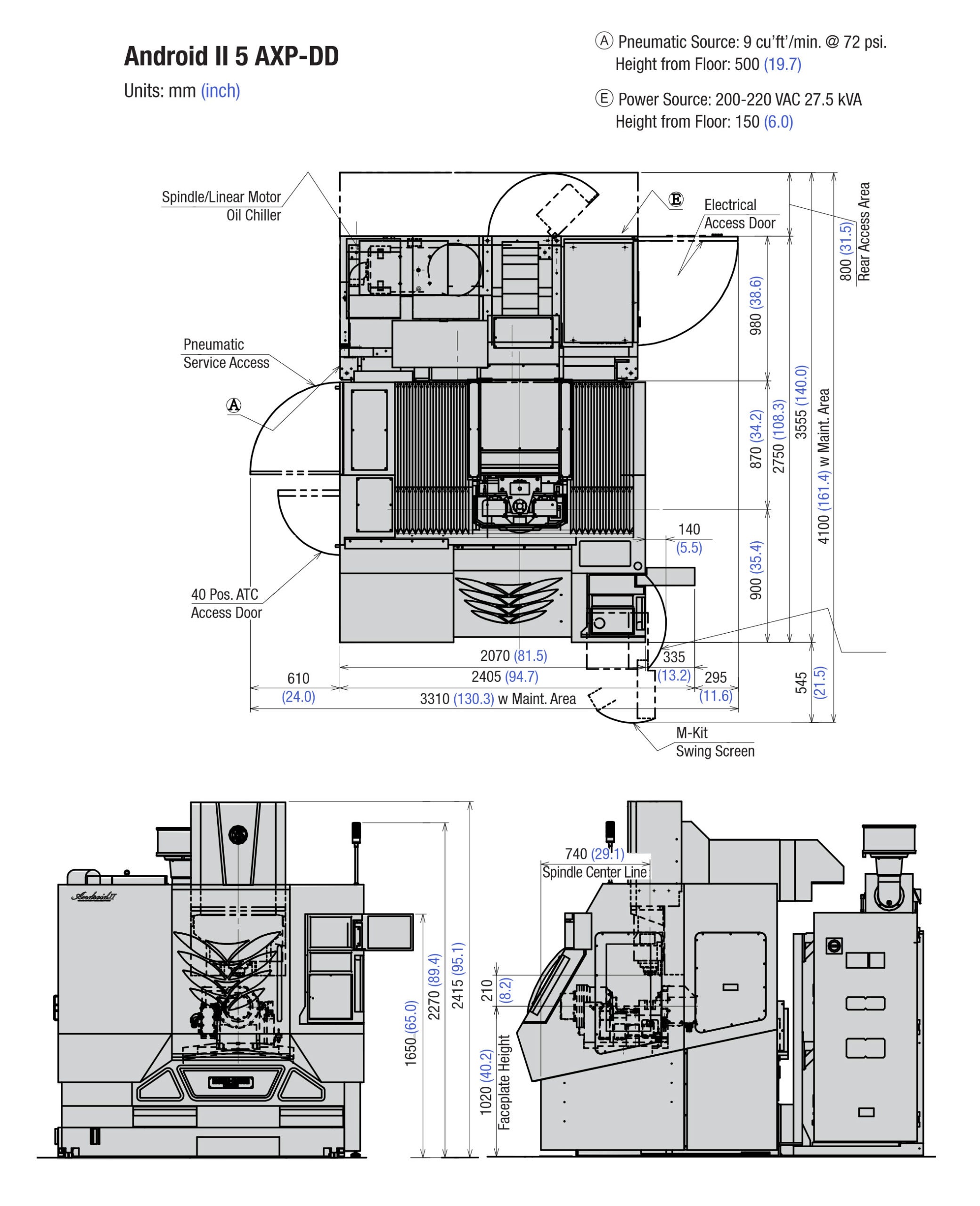

| Model | ANDROID II 5AXP-DD |

|---|---|

| Machine Travels: X x Y x Z in (mm) | 17.7 x 13.8 x 7.9 (450 x 350 x 200) |

| Rotary Table Size dia: in (mm) | 5.9 (150) |

| Max. Workpiece Dia: in (mm) | 7.87 (200) |

| Max Table Load: lb. (kg) | 66 (30) |

| Tilting B-Axis Range: degrees | -90 to +5 |

| Rotary Table Height from Flood: in(mm) | 40.16 (1020) |

| Max Rotation Speed Tilt Axis: RPM | 100 |

| Max Rotation Speed Rotary Axis: RPM | 150 |

| Indexing Accuracy Both Axes: arc sec. | ± 4 |

| Spindle Speed | 3,000 ~ 60,000 RPM |

| Spindle HP | 5 |

| Spindle Lubrication | Oil Mist |

| Spindle Taper | 1/10 taper (Two-plane constraint) |

| Tool Shank | HSK-E25 |

| Tool Changer Size | 20 Position Standard (Optional: 40, 60, 100) |

| Positioning Accuracy/Repeatability: in (μm) | ±0.000039/±0.0000079 (±1.0/±0.2) Full Stroke |

| Table to Spindle Nose Distance: in (mm) | 8.27 (210) |

| Machine Table Height from Floor: in (mm) | 29.5 (750) |

| 745 Hole Positioning Accuracy: in (μm) | ±0.00006 (±1.5) |

| Spindle Air Purge | Standard |

| Air Blast through Spindle | NA |

| Oil Mist with Collector | Optional |

| Linear Scales X, Y, Z – axes | Heidenhain 0.002µm (2nm) Standard |

| Rapid Traverse Speed: in/min. (m/min.) | 590 (15) |

| Cutting Speed (Normal Mode): in/min. (mm/min.) | 0.04 – 394 (1 ~ 10,000) |

| Cutting Speed (GR Super PC Mode): in/min. (m/min.) | 590 (15) |

| Dust Collection System | NA |

| Coolant Tank Capacity: gal (L) | 52.8 (200) |

| Machine Weight: lb (kg) | 14,109 (6,400) |

| Machine Height: in (mm) | 94.9 (2410) |

| Required Floor Space [Mach. Unit]: in (mm) | 81.5 x 108.5 (2070 x 2775) |

| Control Unit | Fanuc 31i-B5 Super High-Speed Processor and Al Contour Control II and Super PC X Function |

| Power Requirements KVA | 200 ~ 220V 19.0 kVA |

| Air Supply | 9 cu.ft./min @ 72 psi |

RELATED SOLUTIONS

-

5-AXIS MACHINING TECHNOLOGY

High-speed, high-precision machines with the power and flexibility to meet any challenge.

learn more -

LINEAR DRIVE TECHNOLOGY

Hyper-accurate machinability for tight tolerances and micro-fine work where the details really matter.

learn more -

HIGH SPEED MACHINING

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

learn more -

GRAPHITE MANUFACTURING

Multiple solutions and expertise in making graphite electrodes.

learn more -

MILLING AUTOMATION

Multiple solutions and expertise in making graphite electrodes.

learn more

-

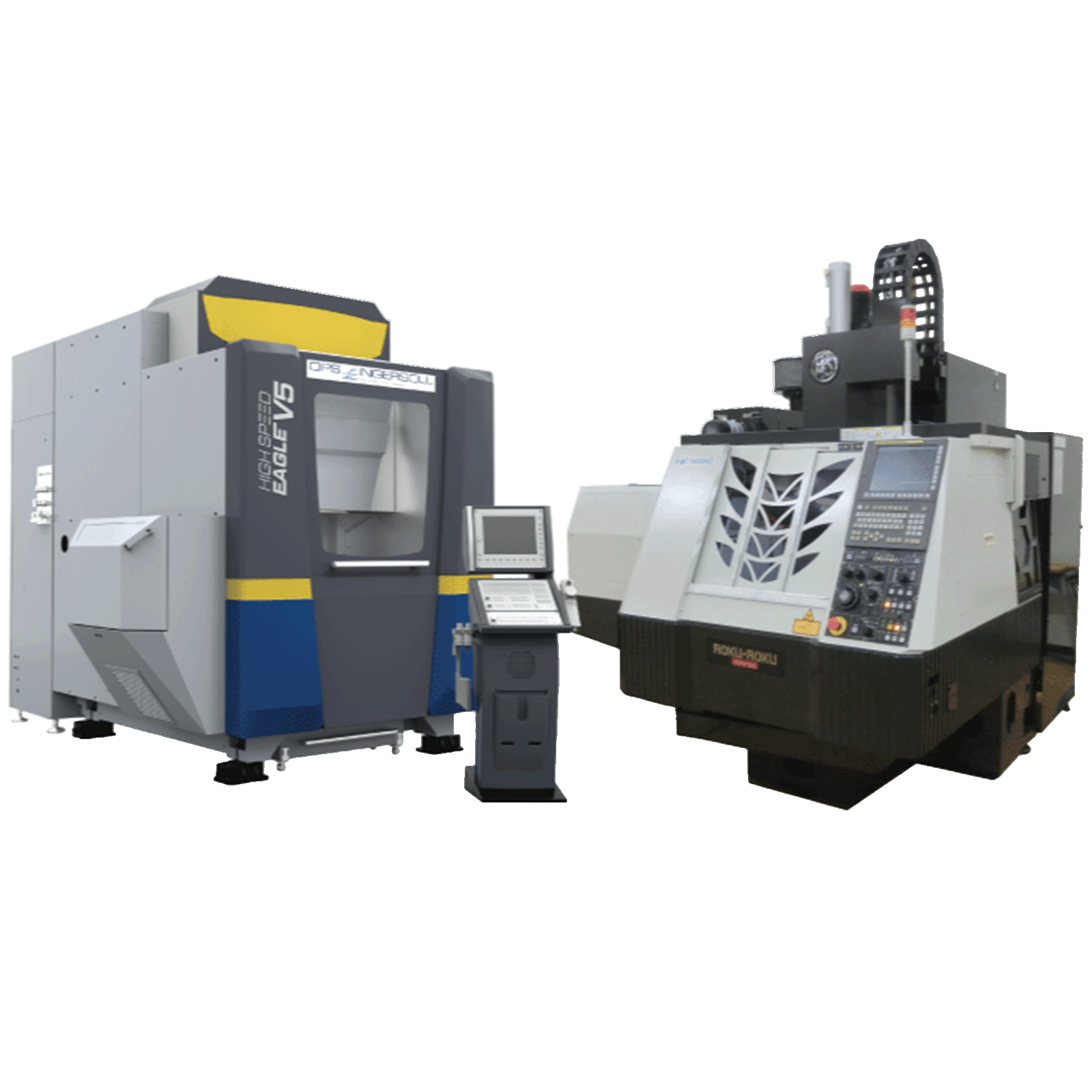

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

Brad McDowell, Quality Tool & Die president Read case study -

"The OPS Ingersoll 5-axis milling machines are fast, accurate, easy to operate and have a small footprint."

Bill Yakle, Owner of Aisling Industries learn more -

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, which saves both time and money. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

Steve Michon, President at Zero Tolerance view case study -

"We used to struggle with tool deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that tool push anymore. Electrodes are so, so much more accurate."

Chad Kearns, Quality Tool & Die vice president Read case study -

"Our biggest supply chain issue is labor, but we have been able to achieve lights-out operation by adding the MC Machinery equipment. We have kept costs down while improving accuracy and doing more with the same number of employees."

Todd Doerfert, Operations Manager at Mantz Automation learn more -

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

John TerBeek, Co-Owner at TerBeek Molding & Tool view case study