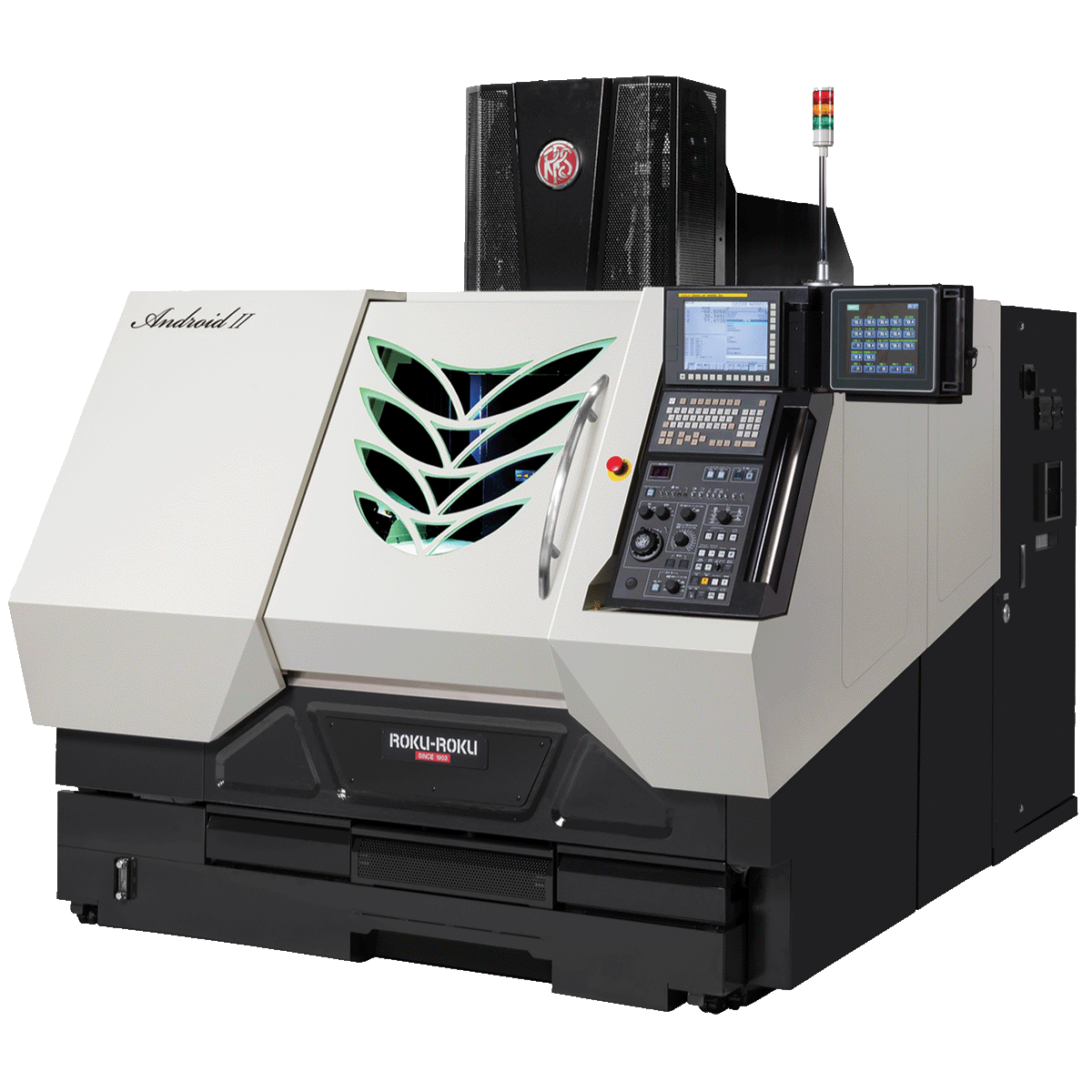

A fast, flexible 5-axis machining solution built to deliver the highest degree of precision needed for today’s workpieces.

LEARN MORE5-axis machining is ideal for highly complex and detailed cutting on hard-to-reach surfaces. We have the superior lineup of some of the most advanced and accurate equipment in the world.

Our 5-axis machines have the precision, speed and durability to handle tough jobs. Adding automation to any of our 5-axis products can increase productivity, efficiency and your bottom line.

When a project requires the absolute best in terms of micro-fine detail work that can stand up to any working environment, you need a machine that can deliver precise, accurate work that’s a cut above the rest.

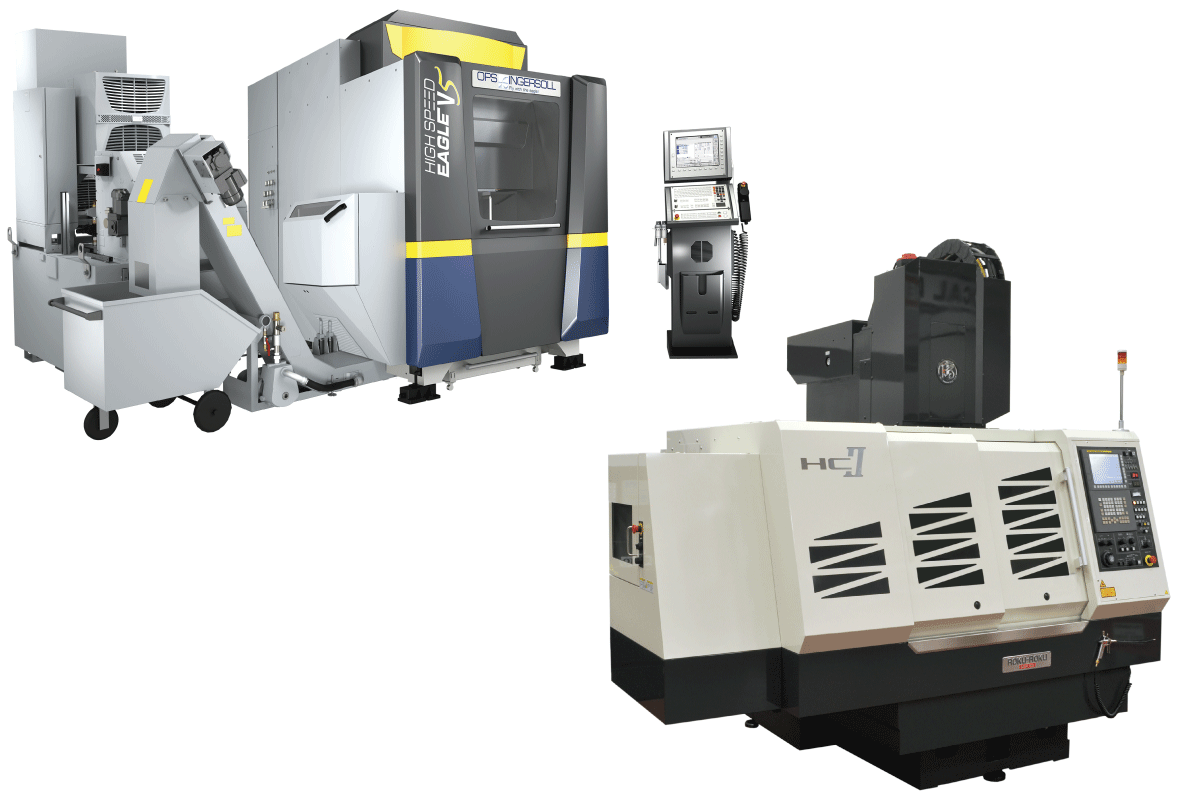

Enter the linear-drive milling machines: the ideal solution for high-speed, micro-fine, macro-profitable production in any application that requires extreme precision, attention to detail, and fast, consistent production.

These machines are inspected to the highest standards with laser-compensation inspections on all axes; dynamic spindle balancing to calibrate spindle displacement, speed, and acceleration; circularity and geometrical accuracy calibration to ensure precise 3D movement; and painstaking precision alignment.

This level of accuracy is unparalleled in the industry!

We only offer the highest quality high-speed 3 and 5 axis machining centers.

Our staff of highly skilled engineers can tackle the most challenging applications and share the skills necessary to make our customers more profitable while using some of the world’s most accurate machines.

Graphite and hard-milling machines combine industry-leading graphite milling with hard-milling capabilities. The benefits of these ‘hybrid’ machines go far beyond convenience.

The result is a fast, accurate, reliable and versatile vertical milling machine.

That’s the kind of efficiency that can make a serious impact on your business by helping you minimize costs while you maximize profits and productivity.

Add in our strong engineering support and you have a highly capable milling machine to get your business where it needs to be.

With milling automation from MC Machinery Systems, customers can greatly increase throughput and maximize their resources.

Milling automation can keep your process in house, improve process control and significantly reduce lead times. Milling automation solutions can lower operating costs, reduce lead times, increase output and more.