“Breadth and Depth” of Application Support Sets MC Machinery Apart

“Whether it’s programming a tool path, trying to adjust power settings, which wire to use, whether there’s trouble in the guides, it’s quite impressive how Mitsubishi delivers that so readily, so efficiently and so on time. They’re on their toes with all types of service no matter how small or how big the problem.”

Crafts Technology President and General Manager Jeffrey Taylor

The Challenge

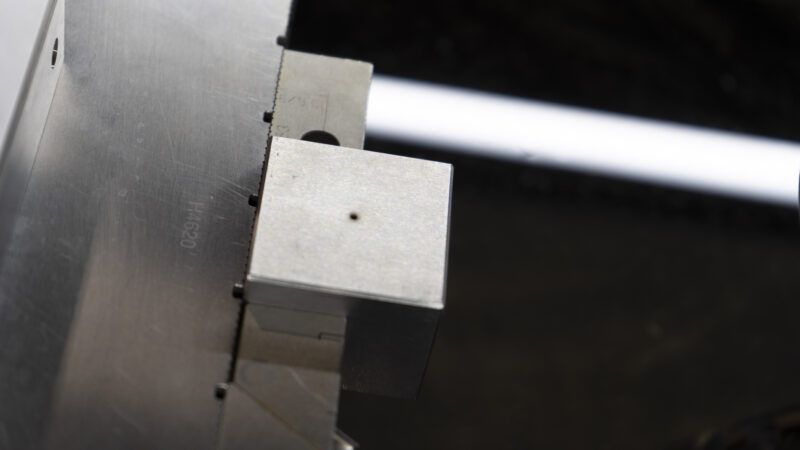

Crafts Technology, a high-precision provider of tailor-made cemented tungsten carbide solutions, purchased its first Mitsubishi EDM from MC Machinery in 2017.

MC Machinery’s comprehensive and knowledgeable application support is what led the Elk Grove Village, Ill. company to buy six more Mitsubishi wire and sinker EDMs, which make the tungsten carbide components used in demanding applications for industries including aerospace, automotive, precision rotary cutting, medical, electronics, and fluid handling and dispensing.

The biggest advantage has been MC Machinery’s application support, which is what set Mitsubishi EDMs apart from the start, said Crafts Technology President and General Manager Jeffrey Taylor.

“When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has,” Taylor said.

The Solution

To Crafts Technology, that expertise is what distinguishes MC Machinery Systems, Inc./Mitsubishi EDM.

“It wasn’t just how the machine could work and it wasn’t just the reliability of the machine and the service–although that was very important–but really it was how they engaged with us on what we wanted to do with the machine,” Taylor said. “Their application expertise is premier in the industry. That’s really what we wanted more than anything: Assistance on how to produce, how to cut and how to synchronize at the highest rates and get the best finishes.”

In the aerospace industry, the number of holes that can be made with a tool determines that tool’s overall value, Taylor said.

MC Machinery’s EDM applications experts worked with Crafts Technology to design these high-value tools.

Crafts Technology Production Manager Vineel Sarup said that his team routinely consults with MC Machinery.

“We talk to the wire or sinker experts and they run the task piece for us and tell us the settings,” Sarup said. “Not only that, programming is easier and the machines are very user friendly.”

The company also uses EDM consumables from MC Machinery’s Consumable Product Group.

“Their consumables are also the highest quality,” Taylor said. “We really don’t want to take any chances. We invested in the best machines and want to follow that up with investing in the best consumables.”