On the Right Track

Doing things small or on the down low isn’t exactly Blake Hamar’s style. It’s no wonder he found his way to Texas, where his automotive accessories manufacturing company Cali Raised LED occupies about 40,000 square feet in Fort Worth’s Sun Valley Industrial Park.

Ten years ago, as a high school sophomore in Southern California, Hamar started selling third-party LED lighting and light truck accessories online and out of an RV trailer at trade shows.

As an ambitious young entrepreneur, Hamar saw a gap in the marketplace for mounting options for truck LED lights. He rented a 2,000-square-foot industrial space in Buena Park, Calif., bought a plasma table and small press brake to make the mounts, and began selling full mounting kits with lights.

“So the problem was that in the lighting market, there were either really, really cheap lights that didn’t work well or high-quality lights that were insanely expensive,” he said. “So I was able to find a solution to meet people in the middle, with products that are affordable but still made with quality manufacturing.”

That worked out so well that customers started asking for more branded products like skid plates and bumpers. In 2019, after graduating from high school, Hamar moved what was now formally called Cali Raised LED from California to Fort Worth to better position it for continued growth.

Barely five years later, the 26-year-old now leads a company that has evolved from selling third-party products out of a trailer into manufacturing over 600 vehicle-specific off-road accessories including bumpers, rock rails, auxiliary lighting, catalytic converter shields, molle panels, and skid plates. Hamar also started a job shop called Apex Fabworks that provides laser cutting, welding and other contract manufacturing services at the same location.

“Since moving to Fort Worth in 2019, we went from a 2,000-square-foot facility to over 40,000 square feet across three acres,” he said. “We went from eight employees to upwards of 45 employees, and the business has grown over 700 percent since the move five years ago.”

Hamar used the plasma until moving to Texas, when he bought a couple of CO2 lasers. As the expanding product line required more manufacturing and increasing consumer demand required faster production, he shopped around extensively for higher performance fabrication equipment.

A new Mitsubishi GX-F ADVANCED 6kW fiber laser was installed in December 2022, followed shortly by the SmartFlex Element Type R laser automation system and a Diamond BH hybrid press brake with the VIDERE operator support system.

“After we had our Mitsubishi laser for a few months, we realized that we needed to get automation on it because that machine was just so efficient and it never had to stop, so our machine operators couldn’t keep up with it,” he said. “Ever since we’ve had the automation tower, it has been an absolute game changer. I think that if you don’t have an automation system on your laser, you are wasting so much opportunity, especially if you’re looking to add additional work to your machine.”

Before adding automation, the company’s lead time was six to eight weeks for most products, Hamar said. Some specialty products, like a bumper, could have a lead time up to 12 weeks.

Now, products are in stock and ready to ship from the on-site warehouse, which gives the company a huge leg up over the competition.

“In our industry, people want their items really fast—you have your awesome new truck and you’re wanting to get outfitted to head on the trails this weekend and that’s where we come in,” he said. “We have our products in stock and ready to ship. Thanks to our advanced manufacturing techniques, we are able to keep up with demand and keep products in stock where our competition can’t.”

Cali Raised LED produces all its products–over 600 SKUs–in house, ranging from L brackets to bumpers.

The Mitsubishi laser cuts anywhere from 26 gauge to 1″ steel, running an average of 14 hours a day. Some days the laser operates 24 hours interrupted, Hamar said.

“A lot of our products we manufacture have really long run times because there’s a ton of little holes in them,” he said. “I would say our average nest is anywhere from 48 minutes to an hour and 10 minutes. Being able to have that automation to just be able to run through the night is super important for us.”

Hamar selected the SmartFlex Element Type R because of its small footprint. And because the laser was already installed and operational, options for configuration were limited.

Cali Raised LED also uses the laser to cut prototype parts.

“Now we have the AR (augmented reality on the GX-F ADVANCED) where you can just throw a piece of metal on the machine, hit capture, and in a minute you have a part versus having to nest a whole nest with a full sheet,” he said. “What it’s been able to do for our product development has been huge.”

The company bought a Mitsubishi Diamond BH hybrid press brake with the VIDERE operator support system in October 2023.

“I think it’s extremely easy to operate,” Hamar said. “If you can operate a basic phone or a computer, you can operate that machine easily. And it’s accurate, where we’re not really ever having to make adjustments to bends.”

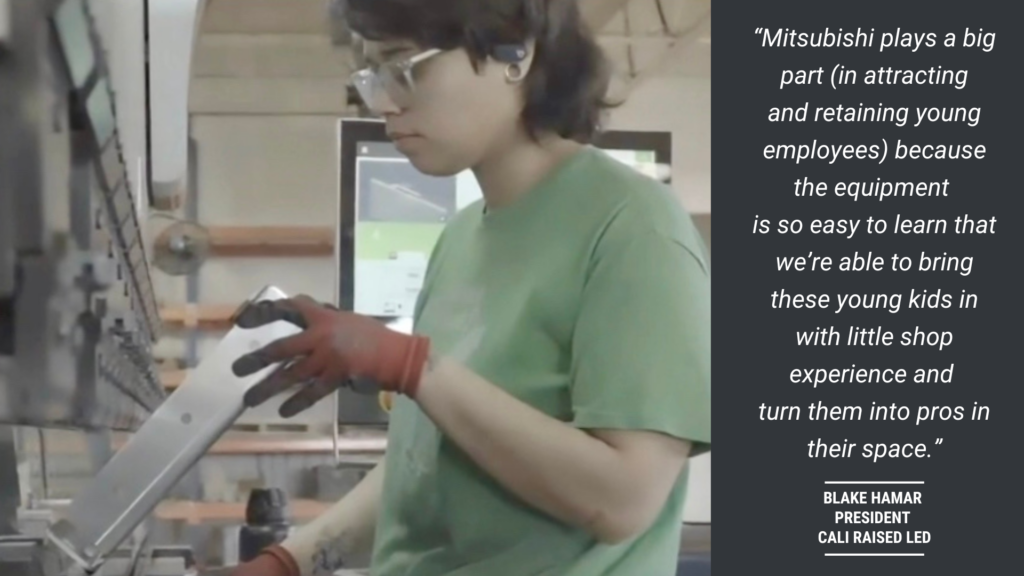

The average age of Cali Raised LED’s more than 40 employees is 25, Hamar said. The company has worked to establish close relationships with Fort Worth-area technical colleges and trade schools. MC Machinery’s equipment has been a big advantage in hiring, training and retaining younger workers.

“Mitsubishi plays a big part because the equipment is so easy to learn that we’re able to bring these young kids in with little shop experience and turn them into pros in their space,” Hamar said.

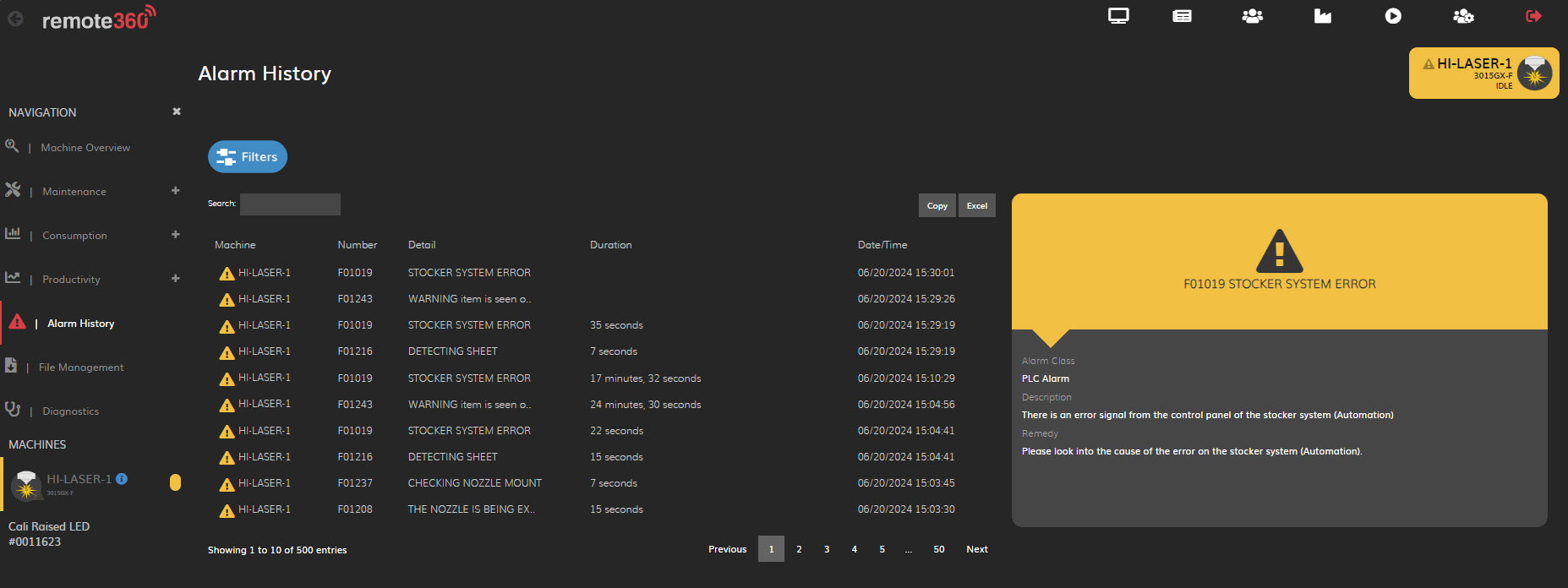

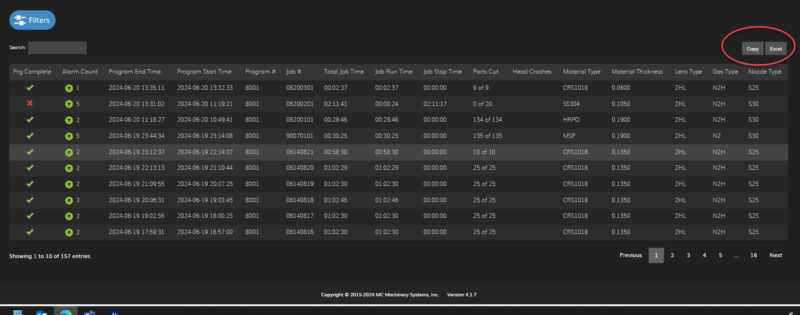

Hamar said one of his favorite things about the GX-F ADVANCED is MC Machinery’s Remote360 machine monitoring system, for two key reasons:

Operational/troubleshooting capabilities: MC Machinery experts can remotely login and troubleshoot problems or answer questions.

“That has blown me away with how quickly they’re able to troubleshoot issues by just logging into the machine,” Hamar said. “For example, when we had our first one-inch job, we had no idea what settings to use and their guy was sitting at the airport watching our machine and we were sending him photos of the cuts and he was literally making cut-condition changes. We ended up making the most beautiful one-inch cut I’ve ever seen.”

Other benefits? The operator (and others) learn what to do from the technician for next time. And downtime is prevented.

“Ninety-nine percent of the time, if you have an issue, it’s just something super little and stupid that’s easily able to be resolved,” he said.

Interested in our fabrication equipment?

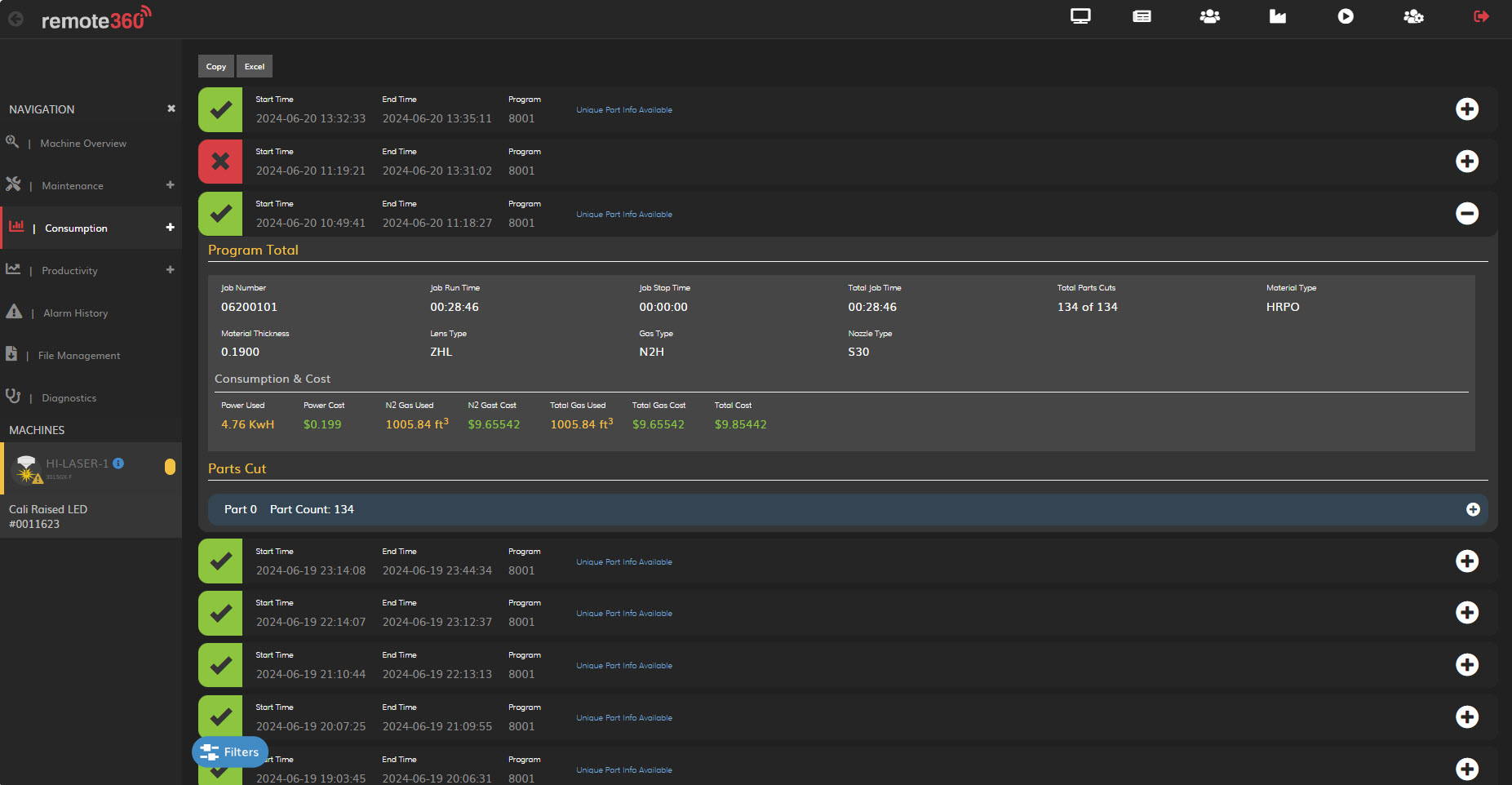

Data and Reporting: The ability to see vast amounts of data from anywhere is very valuable, Hamar said.

“You can truly dial in on what the machine costs to operate,” he said. “Another thing that is really valuable is it tracks all of your errors. So you can reverse engineer and find solutions based on your mistakes. And when I’m on the road, I can quickly see what jobs were run that day. We can be streamlined and efficient.”

He also likes to run regular reports that show the exact time it took to run certain jobs, gas usage and electric usage/cost.

“As a volume producer that builds the same products over and over again, this is so valuable as it helps us tweak our pricing to ensure we can be as competitive as possible,” he said.