MC Machinery Systems will be showcasing the new Mitsubishi AZ600 wire-laser metal 3D printer and the industry-leading Mitsubishi MV2400-ST wire EDM at RAPID+TCT 2024 June 25 through June 27 in Booth 1821.

The Mitsubishi AZ600 melts welding wire with a laser beam to create high-quality 3D structures, producing high-speed, high-precision 3D printing while reducing energy consumption and waste.

Applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

With the same proprietary wire-feeding technology used in Mitsubishi’s industry-leading wire EDMs, a simple command on the machine’s CNC control feeds the exact amount of wire to the target location. Unlike other 3D printers, the wire is in the front of the machine to make it easier to replace. Additionally, it uses commercially available welding wire as feedstock.

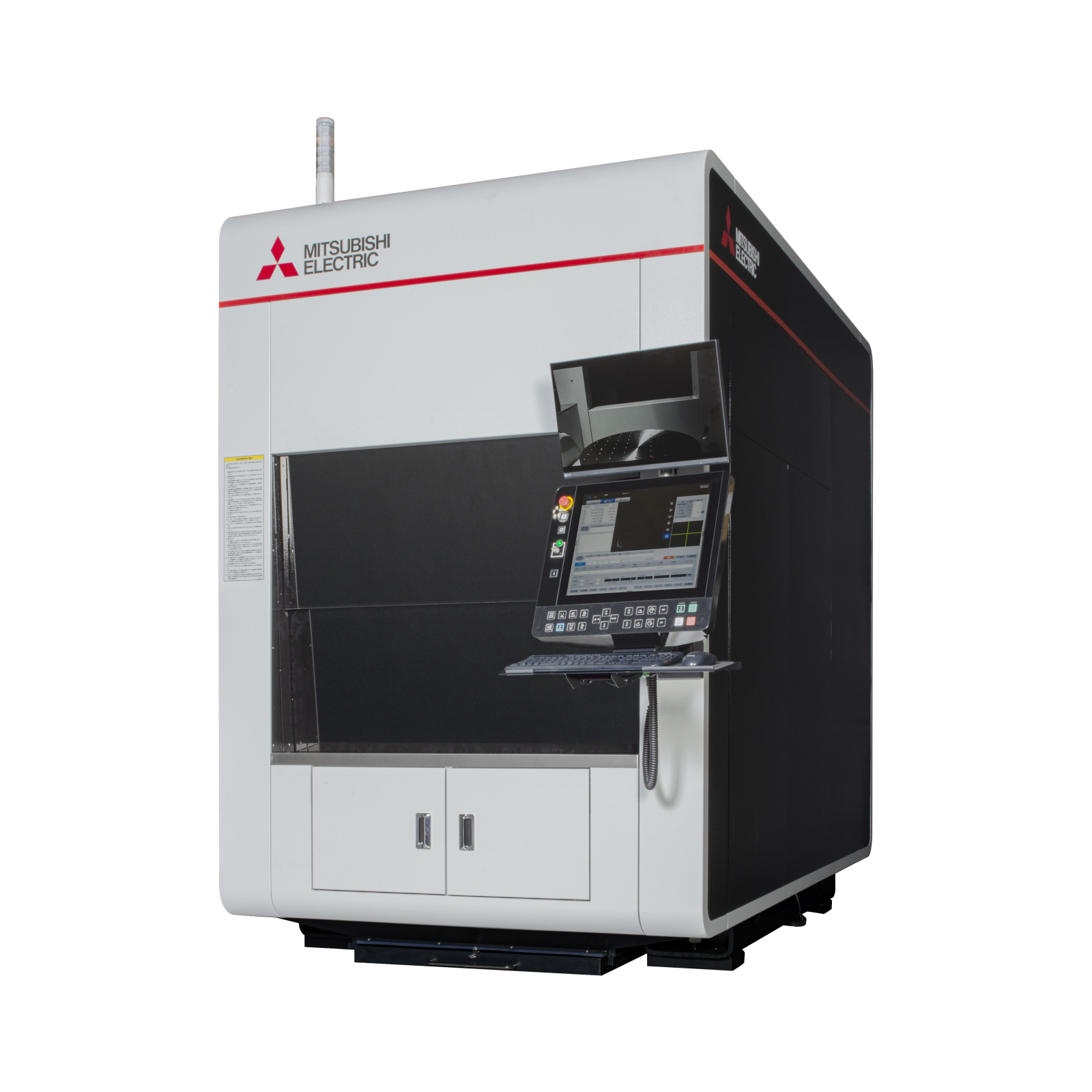

The Mitsubishi MV2400-ST wire EDM is capable of submerged cutting up to 16.5-inches deep and is supported by the most advanced auto-threading system on the market today. With an annealing length of over 21 inches, this system can thread the maximum workpiece height at both the start point and through the gap for broken wire recovery. Like other Mitsubishi wire EDMs, the MV2400-ST has the lowest cost of operation in the industry.