Cross-flow resonators

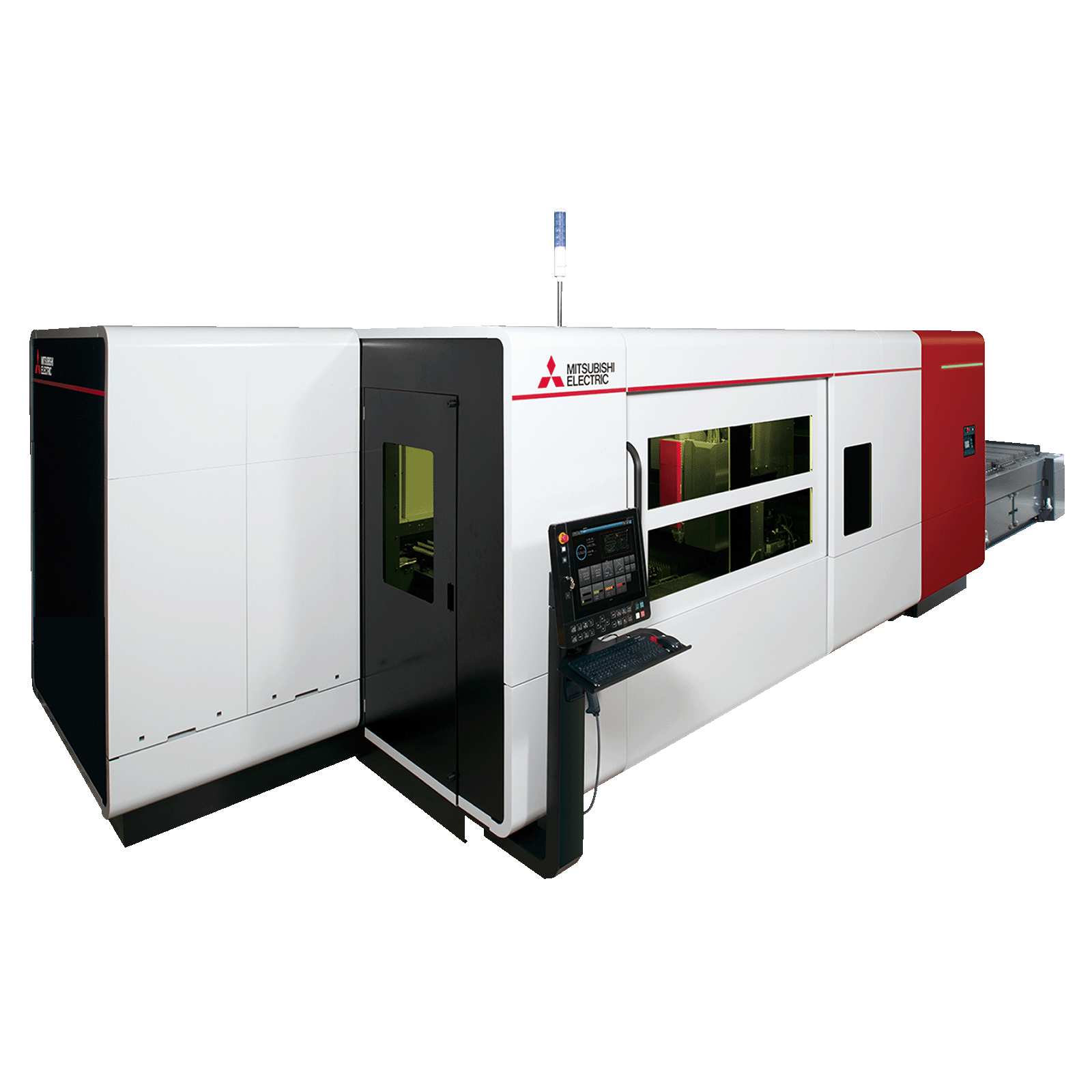

Over 1,500 low-consumption, clean-running laser machining powerhouses sold. 0 replacements needed.

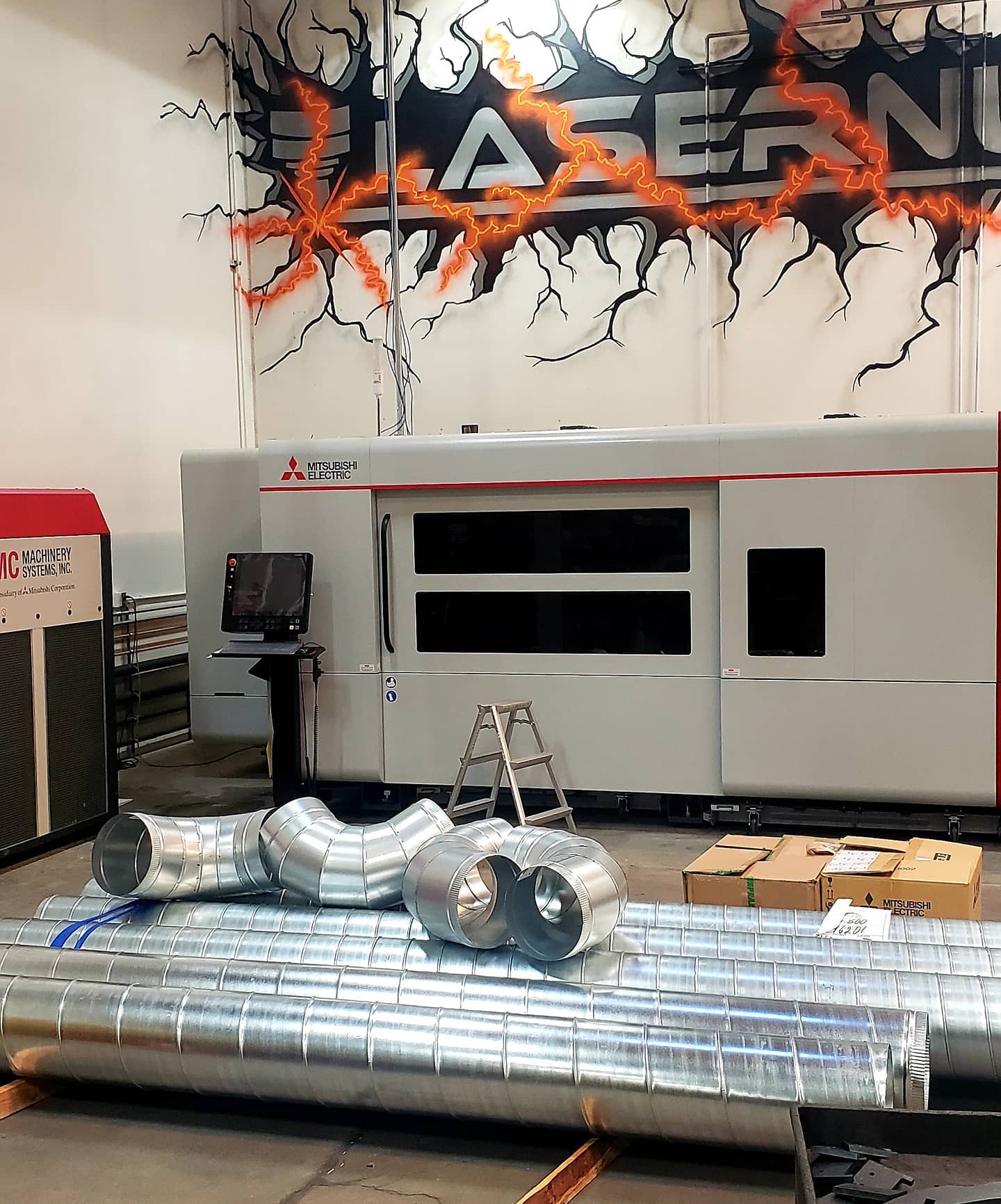

The best laser in the world is only as good as its access to reliable, uninterrupted, productivity-fueling power.

That’s why we’ve developed our own series of cross-flow resonators optimized specifically for Mitsubishi laser machines. But what’s so special about them?

Our cross-flow resonators deliver a unique pulse that results in a sharper beam, leads to cleaner parts, and contributes to a best-in-industry 90% lower gas consumption—all so your maintenance and downtime costs remain as low as possible.

That’s partly why, with more than 1,500 Mitsubishi laser machines sold and not a single replacement required, our cross-flow resonators remain the most reliable on the market.

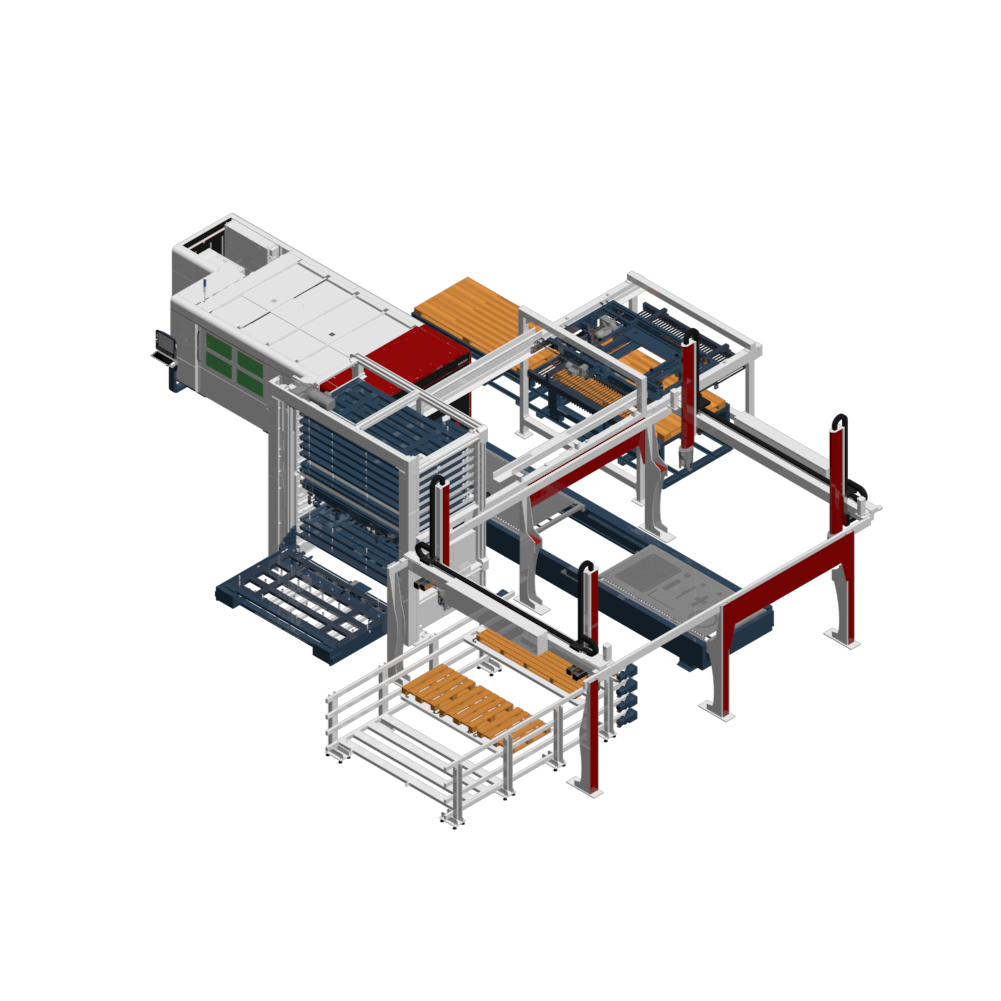

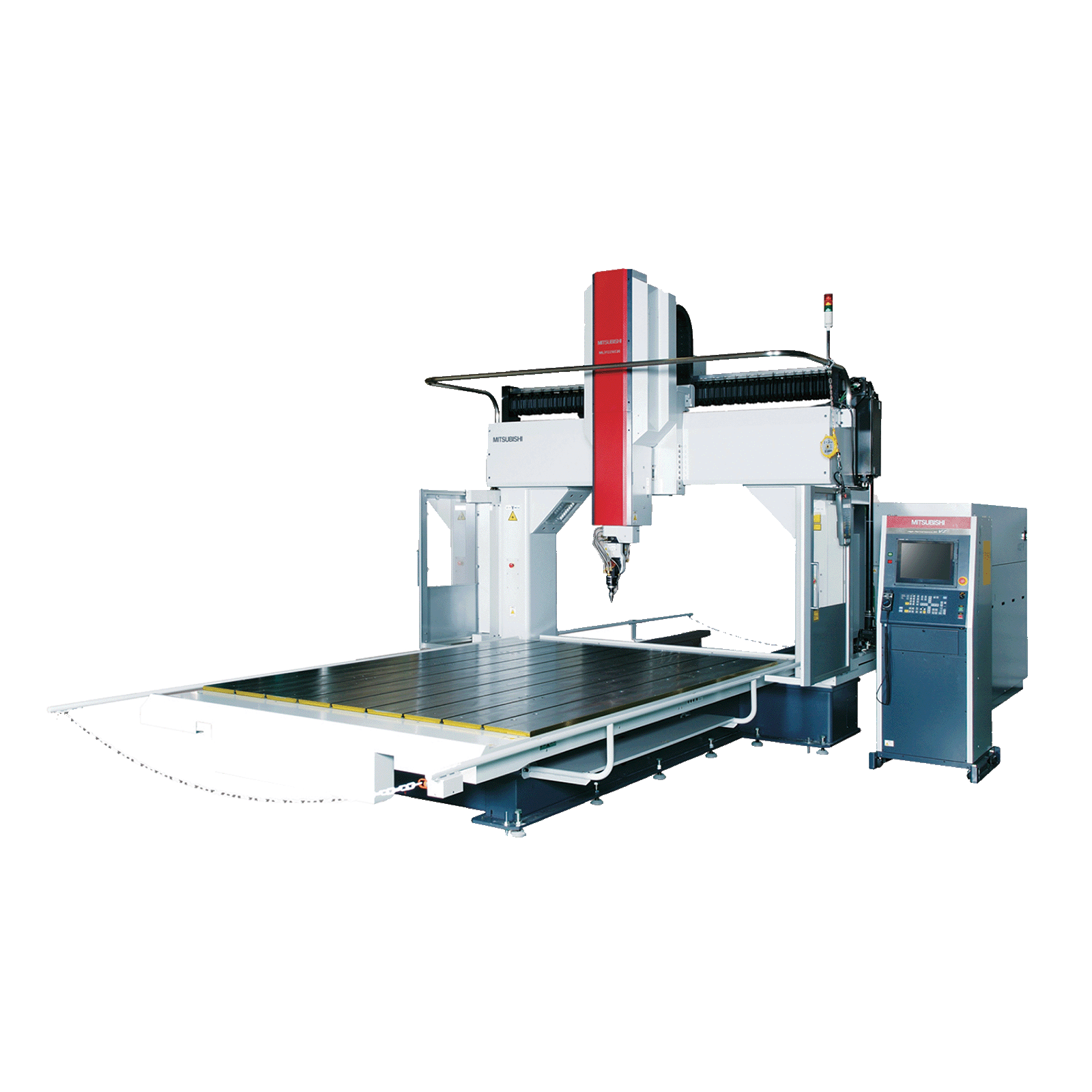

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.