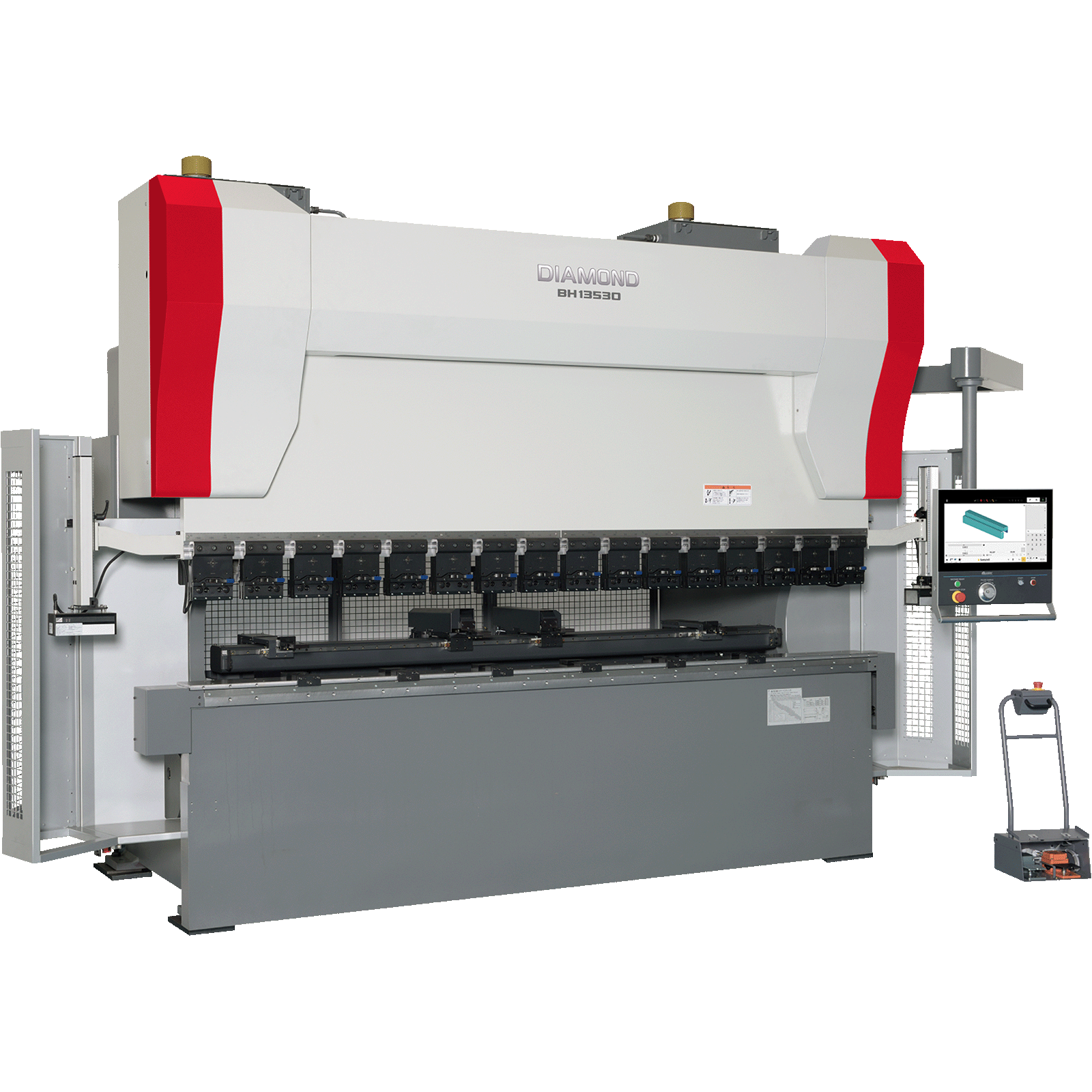

Diamond BB Series

These compact, cost-efficient press brakes are the best choice for quick, quiet, high-quality work.

Featuring an AC servo motor and ball screw mechanism for high-speed productivity and repeatability (± 0.001mm)—brought to you by the originators of the world’s first electric press brake—the BB series ball screw press brake is the reliable, cost-efficient answer for accurate repeat bending work.

But the BB series is more than just a press brake workhorse. Equipped with on-board diagnostics capabilities and an intuitive CNC interface, these electric press brakes are as good for your business as they are for your operators. Quiet operation, environmentally clean, and easy to use, the BB series is the crown jewel of any bending department.

- The electric AC servo motor and ball screw drive mechanism isn’t just fun to say. It achieves performance that outclasses other electric and hybrid press brakes, all while ensuring long-term accuracy and minimum internal wear. The result? A machine you can trust to keep doing everything you need it to, day after day.

COST-EFFICIENT OPERATION

- Form complex parts easily and cost-efficiently. The BB series is built from the ground up to deliver the best results with the fewest required resources. It’s soft on electricity consumption but still tough on any project your shop can throw at it.

MAXIMUM RESULTS, MINIMUM EFFORT

- An easy, intuitive 22” color multi-touchscreen running Windows makes everything from day-to-day operation and programming to 3D simulation simple and quick. That means that this machine has the potential to achieve peak performance in nearly any scenario under any operator. Finally—simple, stress-free functionality.

- The upper beam drive system enables high-speed movement and incredible ram repeat-stop accuracy all with the industry’s fastest cycle time 2.1s.

- The high-speed, high-precision back gauge has a four-micron positioning accuracy for uncompromising product quality thanks to Mitsubishi motor technology.

- As an electric press brake, the BB series causes minimal noise and uses no oil, making it friendly to both your working environment and the environment at large.

- With automatic thickness detection & compensation, angular irregularities are minimized due to material thickness with no added options or external measurement device needed; the BB series holds tolerances some machines can only hope to do with angle measurement systems

COMPONENTS:

- High-speed ball screw drive (fastest cycle time in its class)

- Highly stable repeat accuracy, ball screw drive (1-micron repeat accuracy) +001mm

- 6” (650mm) X-axis max gauge distance 4-micron back gauge repeat accuracy) +.004mm

- Pulse handle with axis control & bending support (standard)

- Standard 4-axis back gauge BB40/60 (optional 5 or 6-axis back gauge)

- Standard 5-axis back gauge BB30 (optional 6-axis back gauge)

- Interlocked rear access gate (standard)

- LED lighting over back gauge and front work area (standard)

- Simple up/down foot pedal safety system (standard)

- Mitsubishi servo amplifiers and motors

- European one-touch tool holders (standard) – WATCH VIDEO

ON-BOARD PRODUCTIVITY:

- Automatic thickness detection/compensation capabilities for accurately measuring part thickness on the fly

- Work efficiency analysis capabilities to ensure you’re always working at peak production

USER INTERFACE:

- USB & Lan peripheral interfacing

- CNC control with 22” multi-touchscreen LCD display with 3D simulation, 2D/3D draw functionality, and custom multiuser & multilanguage interface

SYSTEM INFORMATION:

- Microsoft Windows operating system (16GB)

- Large program capacity (64GB) with a comprehensive tool library

OPTIONAL COMPONENTS:

- Angle measurement

- Sheet supports

- Front support table (BB4013/BB6013)

- Moveable foot pedal (BB6020)

- Laser finger guarding

- Extra CNC back gauge axes (up to 6 axes)

- Hydraulic clamping from Wila and Wilson

- Back gauge touch sensors

- Tooling packages from Wila, Wilson, and Mate

- Interlocked side gates over the C-frames

- American segmented upper punch holders

- Small segmented European punch holders

- DiamondBend offline programming software –WATCH VIDEO

- VIDERE operator support system (BB6020)

- Increased open height

- Bar code reader

| MODEL | BB306 | BB4013 | BB6013 | BB6020 |

| Press Force: metric (US) | 28 (30) | 36 (40) | 55 (60) | 55 (60) |

| Bending Length: mm (in) | 630 (25) | 1,260 (50) | 1,300 (51) | 2,100 (83) |

| Back Gauge Axis | 5/6 | 4/5/6 | 4/5/6 | 4/5/6 |

| Open Height: mm (in) | 430 (17) | |||

| Ram Stroke: mm (in) | 150 (6) | |||

| Gap Depth: mm (in) | 200 (8) | 100 (4) | 400 (16) | 400 (16) |

| Distance Between Frames: mm (in) | 700 (28) | 1,300 (51) | 900 (35) | 1,700 (67) |

| Strokes/Hour (SPH) | 1,714 | |||

RELATED SOLUTIONS

-

ELECTRIC PRESS BRAKES

Mitsubishi electric press brakes are known for speed, efficiency, and reliability.

learn more -

HYBRID PRESS BRAKES

This Mitsubishi dual-drive hybrid press brake makes short work of any project with its high speed, energy-efficient operation.

learn more -

HYDRAULIC PRESS BRAKES

High productivity, heavy-duty bending performance, and intuitive operation in a cost-efficient package.

learn more -

PRESS BRAKE AUTOMATION

Real-time information from this game-changing Mitsubishi tool changer lets any press brake operator perform at their best.

learn more

-

"The accuracy and repeatability are outstanding. I had one job running for five days straight—there was no difference from the first part bent on day one to the last part bent on day five. All of this plus the reduced setup time translates into higher profitability."

Milan Popik Jr, Owner at Metal Tronics view case study -

"“Press brake operators of all skill levels can easily set up complex jobs. This saves tremendous time and resources. Press brakes have not changed that much mechanically over the years, but technology like automation and diagnostics can really set you apart from the competition."

Eugenio Martin, Lynam Inc. manufacturing engineering manager