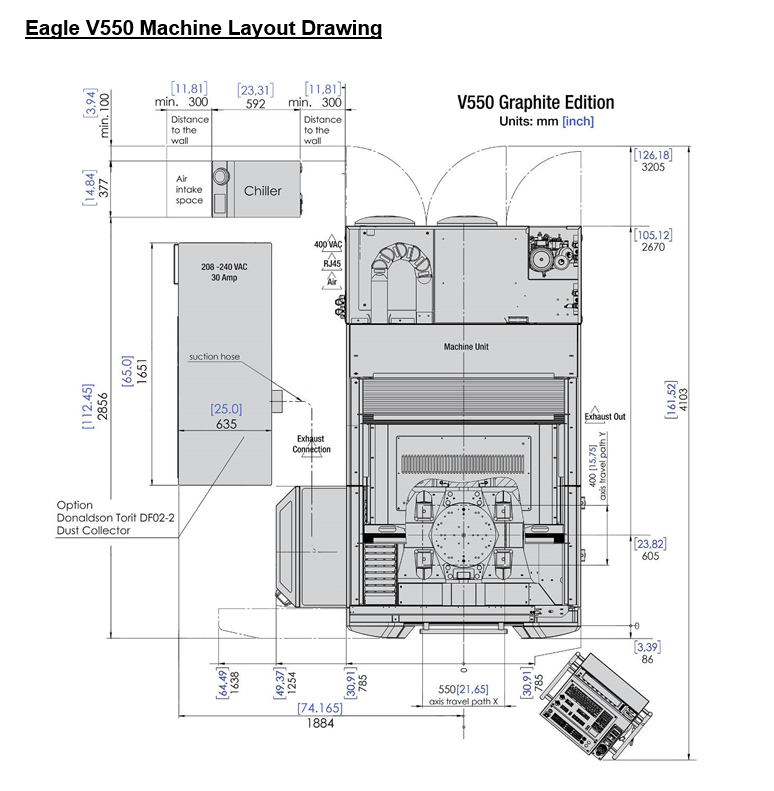

Eagle V550 (5-axis)

High-speed, high-precision 5-axis machining for small graphite electrodes, mold/die components, and more – all in a small footprint.

There’s nothing more frustrating than pouring time, energy, and resources into a machine fleet that—despite your best efforts—just can’t seem to return the favor. Then you throw the new challenges facing today’s machine shops into the mix: things like an ever-shrinking skilled labor pool, the need to be faster and more efficient than ever via automation, and other thorny problems.

Relief for the challenging issues facing your machine shop comes on swift wings—in the form of the high-speed Eagle V550: a high-speed, ultra-rigid 5-axis vertical machining center (VMC) specially designed to cut the difficulty out of graphite machining jobs.

HEAVY-DUTY PERFORMANCE YOU CAN COUNT ON

- Built and designed highly rigid and incredibly precise, the Eagle V550 gantry-type 5-axis VMC is one machine your workers, your customers, and your bottom line can all count on. Whatever the job or timeline, you can trust the Eagle line’s superior craftsmanship and components to carry the day.

EASY, INTUITIVE OPERATION THAT MAKES A DIFFERENCE

- The Eagle V550 comes with an advanced CNC control unit designed to help your workers get the most out of your investment—both in the short term and well into the future. Easy to train and easy to operate, the V550 brings efficient, cost-effective labor to the middle of your shop floor.

FLEXIBLE, FUTURE-FRIENDLY DESIGN

- Automation isn’t just a buzzword. It’s your ticket to new levels of efficiency and profitability for your business. That’s why every machine in our Eagle line is prepared for automation—as a single machine, inside a standalone cell, or as part of a full, integrated manufacturing line.

The Eagle V550 (Graphite Version) is designed to be an ultra-rigid 5-axis vertical machining center with the capacity to handle a 550-pound workpiece on a 15.75” rotary table surface. The Heidenhain TNC-640 control unit with a 17” display is mounted on a moveable pedestal for optimal positioning convenience. The Eagle V550 is designed with a side opening in the casting to allow robot loading from the right side with pallets up to 15.7” square.

CAPABILITIES:

- Can handle a 550-pound workpiece on a 15.75” table surface

- Allows robot loading from the right side with pallets up to 15.7” square via side opening design

- Achieves high machine rigidity, vibration dampening, working precision, and finish quality via cast iron bed with BIOCAST® design and topology-optimized structure for optimal stiffness and temperature symmetry

- Hits high working speeds via a 20-HP, 42,000-RPM integrated spindle, heavy-duty, roller-type linear guideways, and large-diameter ball screws and linear glass scales in both the X and Y axis

- Performs high-precision cuts with the X, Y, Z, B, and C axis moving simultaneously

- Can easily handle surface machining, spiral contour machining, irregular contour machining and other complex cutting tasks

- Superior drive mobility and power efficiency compared to conventional worm gear setup machines thanks to zero-backlash B axis gear and C-rotary axis direct drive motor with rotary encoders

COMPONENTS:

- Integrated 4/5-axis system (without T-slot table)

- Maximum acceleration: 49 ft/s²

- HF spindle 20 HP, 42,000 RPM, HSK-E40, and 32-position ATC (100-position ATC optional)

- Renishaw infrared measuring probe

- Blum laser system for tool breakage detection and tool length/diameter compensation

- Vibration-dampening cast iron bed with sand-filled BIOCAST® design

- 3-point foundation setup/leveling

- Ball screws with direct drive AC motors

- Absolute measuring with glass scales

- Oil-mist lubricant system, spindle external

- 2-color status light

- Auto lube system, both drives and ways

- Full lining with dust and liquid protection

- LED machine lamp in work area

- Chip tray

- Precision package 3 for 5-axis machines – Temperature-distribution compensation, including:

- ATDC (Automatic Temperature Drift Control)

- 5-axis compensation

- Heidenhain option (kinematics optional)

- Ceramic ball for kinematics accord

USER INTERFACE:

- Heidenhain TNC-640 5-axis simultaneous control

OPTIONAL ACCESSORIES:

- HF spindle 20 HP, 36,000 RPM, HSK-E50 w 32-position ATC

- 100-Position ATC HSK-E40

- 80-Position ATC HSK-E50

- Table clamping and pallet systems from EROWA, Hirschmann, and system 3R

- ICS 2 ATS internal coolant supply with aerosol/dry lubrication

- T-slot table to cover the 4/5-axis (Converts the machine to 3-axis operation)

- Keller exhaust system for graphite and mist collection

- 3-color status light

- Oil-mist suction unit

- Chip conveyor for dry milling (incl: chip bucket)

- DCM (Dynamic Collision Monitoring)

- Multichange Easy Basic Unit (incl: gripper, 40-pos or 5-pos or 4-pos magazine, workpiece change place, and connection to machine)

| Machine Travels: X x Y x Z in (mm) | 21.6 x 15.7 x 15.7 (550 x 400 x 400) |

|---|---|

| B-Axis Tilt Range Degree (RPM) | -120° ~ 60° (25) |

| C-Axis Rotation Range Degree (RPM) | 360° (60) |

| Rotary Table Faceplate: dia. (mm) | 15.75 (400) |

| Max Workpiece Height: Faceplate/Pallet (mm) | 15.7/12.7 (400/325) |

| Max Rotary Table Cap: lb. (kg) | 550 (250) |

| Spindle Speed | 42,000 RPM |

| Spindle HP (S1 100%) | 20 HP (15 kw) |

| Spindle Nose to Table: in (mm) | 2.0 ~ 17.7 (50 ~ 450) |

| Tool Changer Selection | HSK-E40 (32 pos std) / (100 pos optional) |

| X, Y, Z Rapid Speed: in/min. (M/min.) | 1181 (30) |

| Max Workpiece 3-Axis / in/lb. (mm/kg) | X 21.6 x Y 15.7 x Z 15.7 / 1102 ( 550 x 400 x 400 / 500) |

| Machine Weight: lb. (kg) | 15,873 (7,200) |

| Mach Dimensions W-D-H: in (mm) | 79.5 x 110.2 x 96.5 (2,020 x 2,800 x 2,450) |

RELATED SOLUTIONS

-

5-AXIS MACHINING TECHNOLOGY

High-speed, high-precision machines with the power and flexibility to meet any challenge.

learn more -

LINEAR DRIVE TECHNOLOGY

Hyper-accurate machinability for tight tolerances and micro-fine work where the details really matter.

learn more -

HIGH SPEED MACHINING

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

learn more -

GRAPHITE MANUFACTURING

Multiple solutions and expertise in making graphite electrodes.

learn more -

MILLING AUTOMATION

Multiple solutions and expertise in making graphite electrodes.

learn more

-

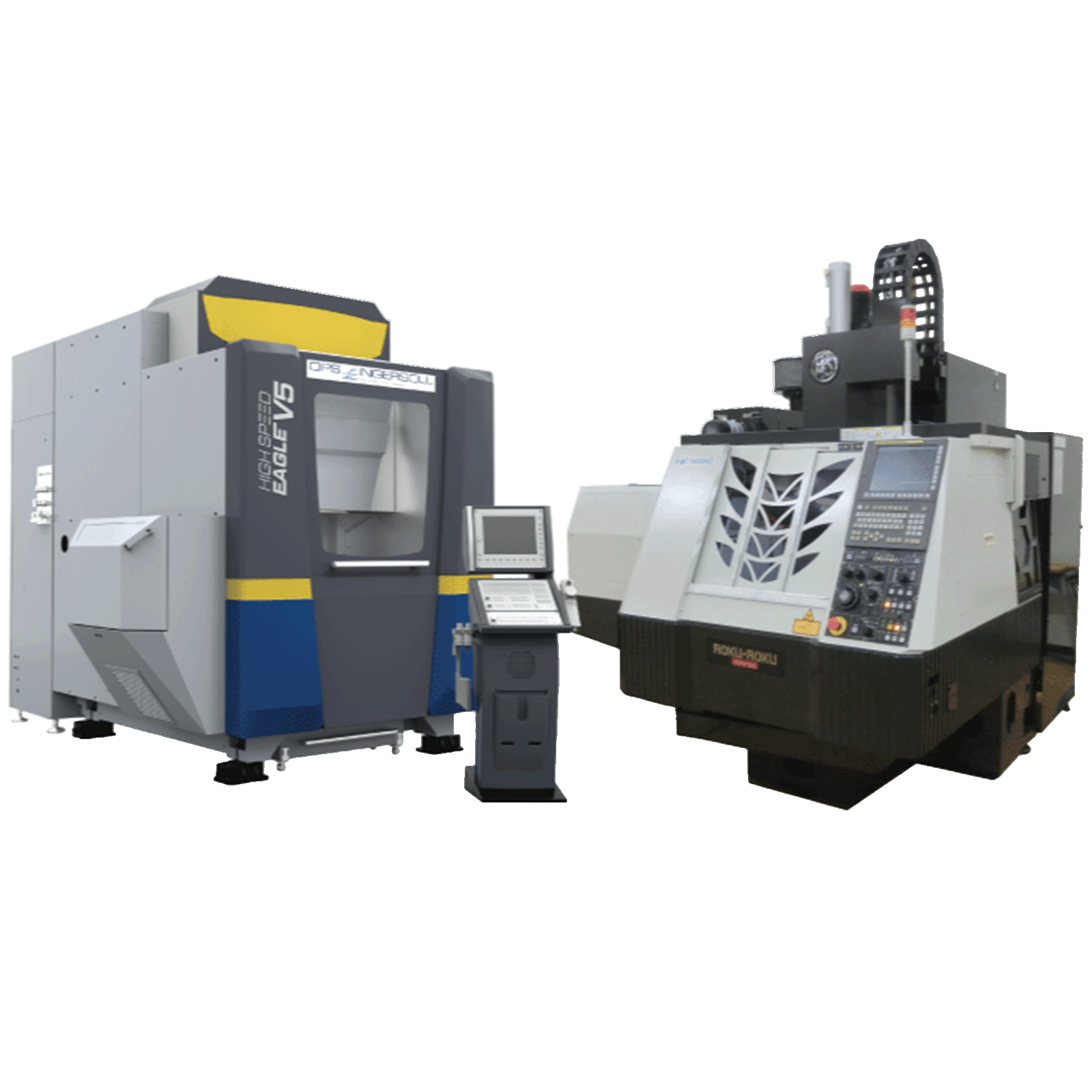

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

Brad McDowell, Quality Tool & Die president Read case study -

"The OPS Ingersoll 5-axis milling machines are fast, accurate, easy to operate and have a small footprint."

Bill Yakle, Owner of Aisling Industries learn more -

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, which saves both time and money. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

Steve Michon, President at Zero Tolerance view case study -

"We used to struggle with tool deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that tool push anymore. Electrodes are so, so much more accurate."

Chad Kearns, Quality Tool & Die vice president Read case study -

"Our biggest supply chain issue is labor, but we have been able to achieve lights-out operation by adding the MC Machinery equipment. We have kept costs down while improving accuracy and doing more with the same number of employees."

Todd Doerfert, Operations Manager at Mantz Automation learn more -

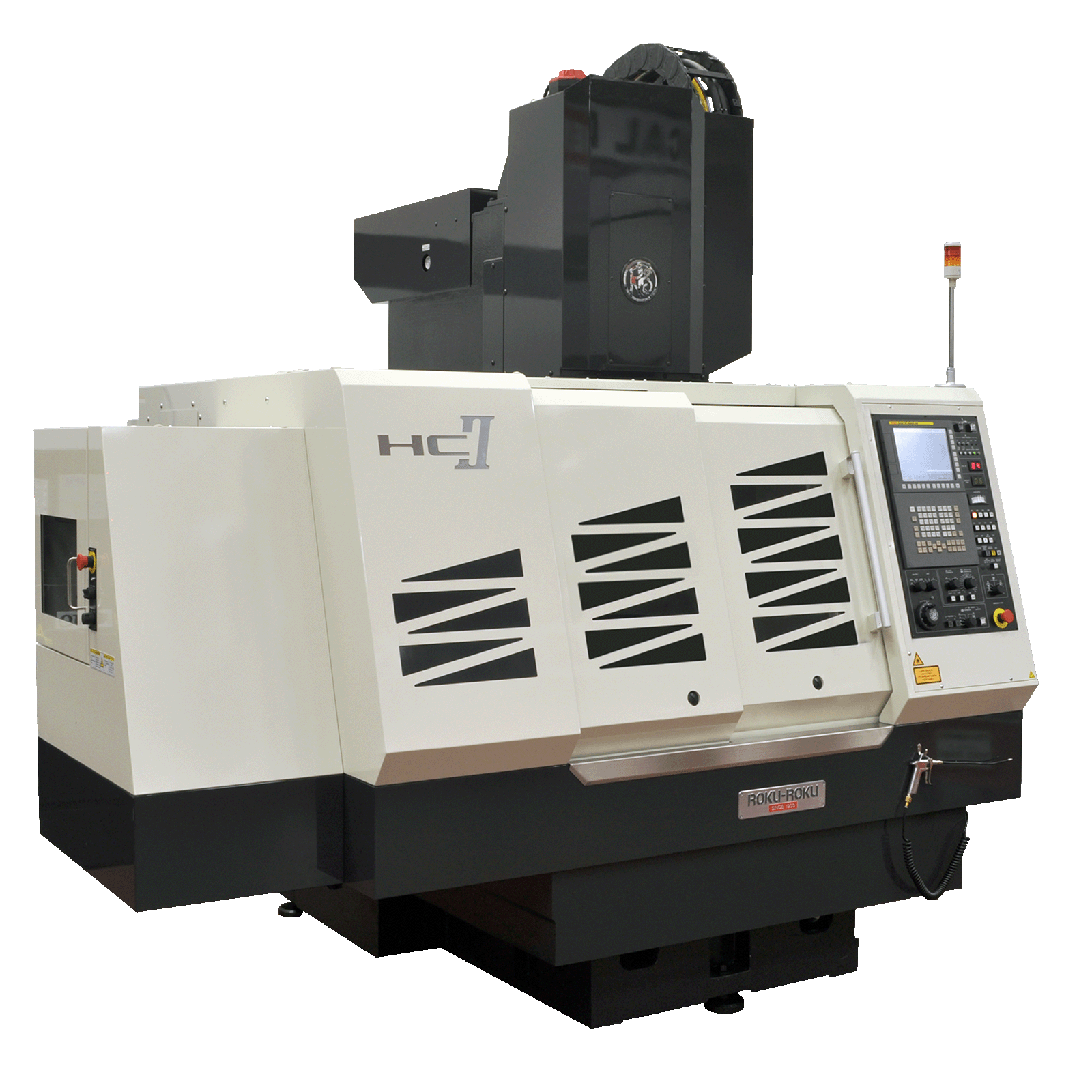

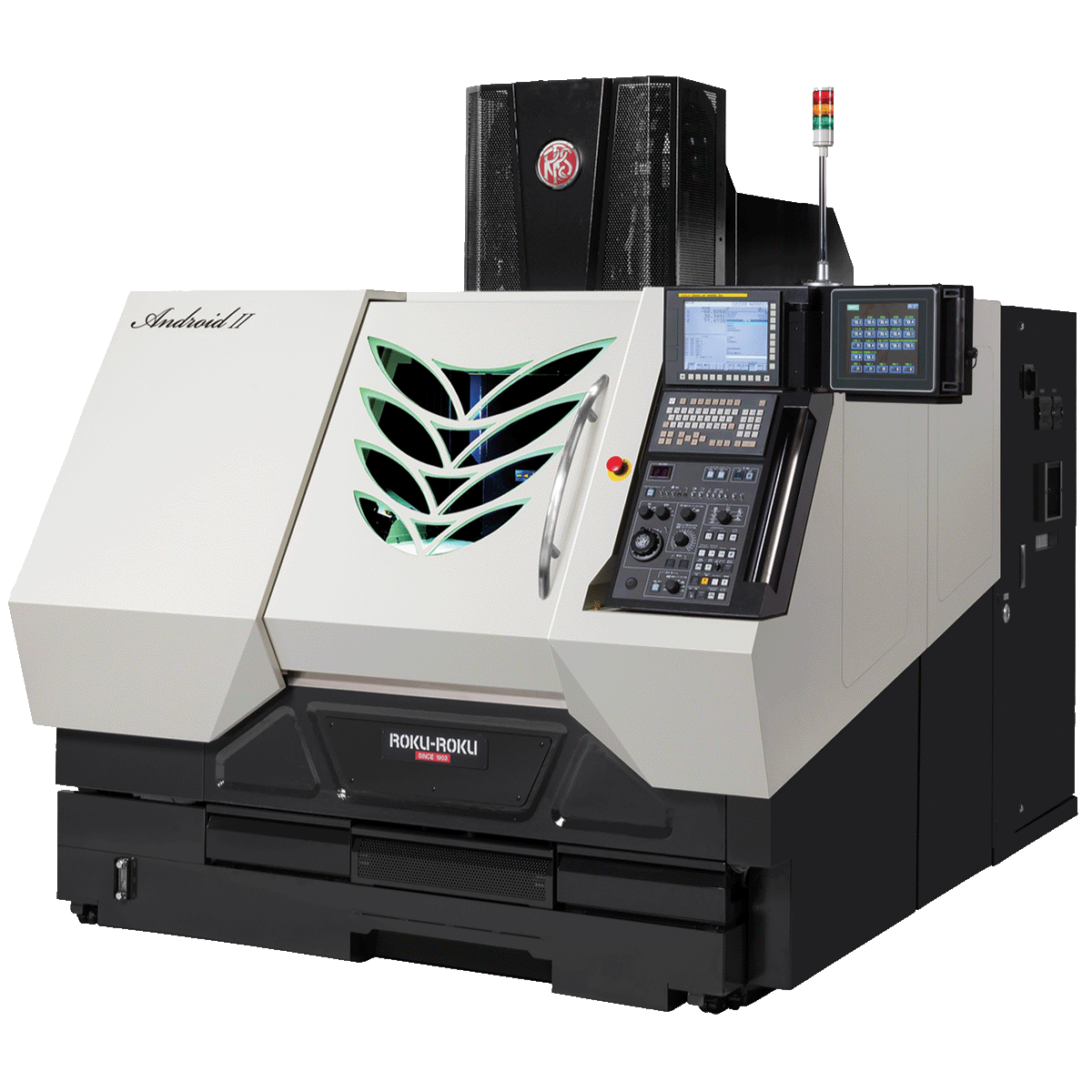

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

John TerBeek, Co-Owner at TerBeek Molding & Tool view case study