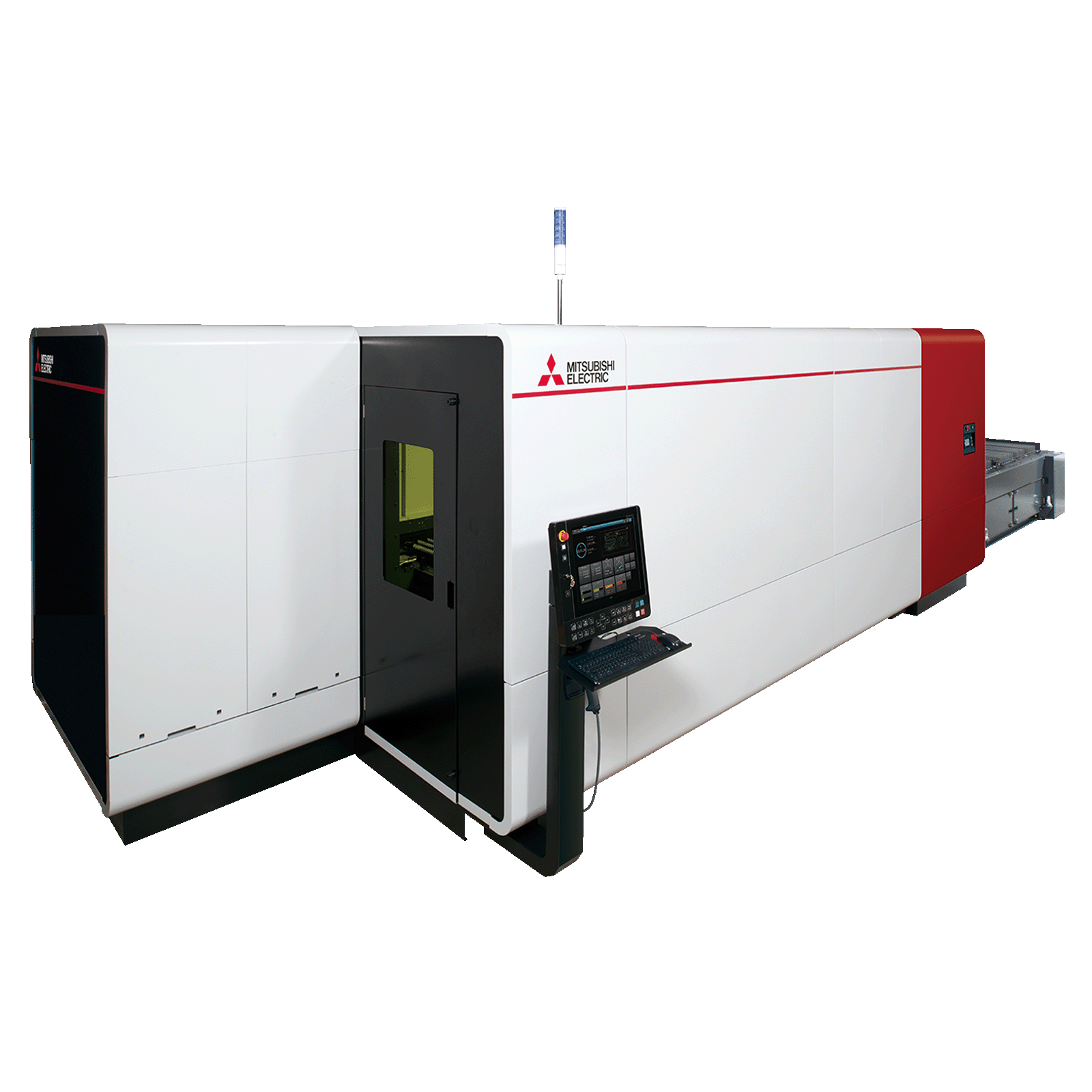

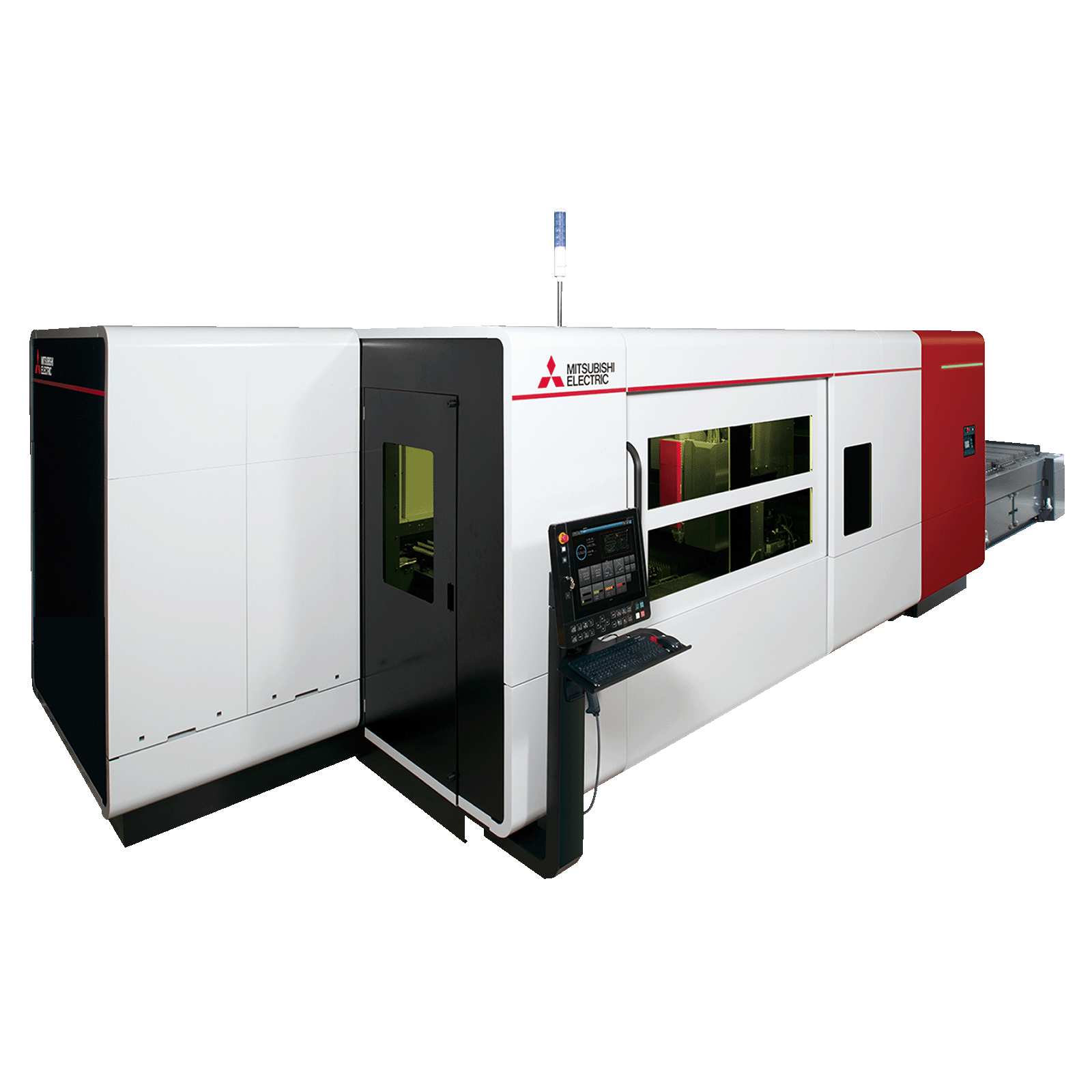

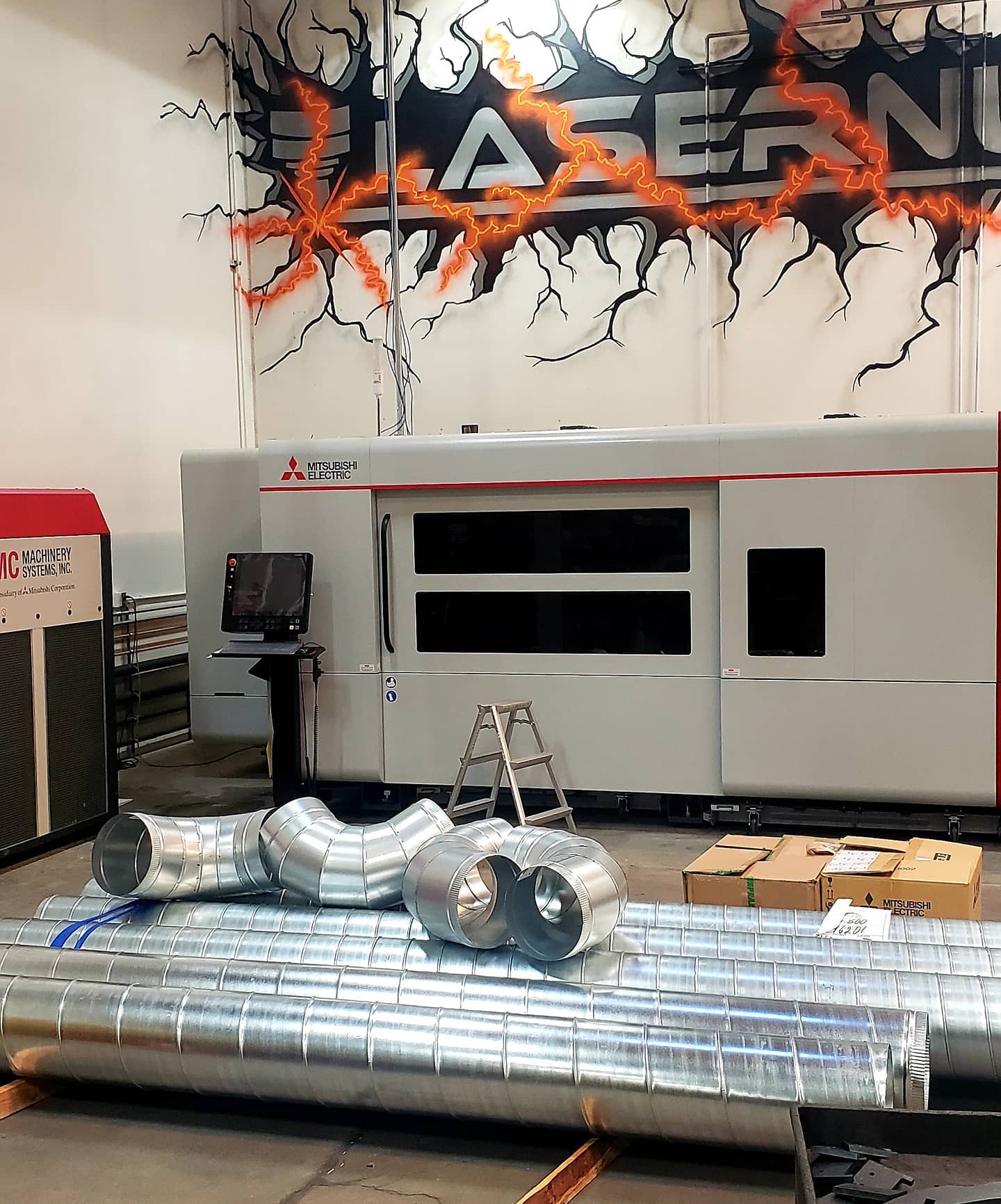

GXL-F Series

Introducing the GXL-F Series: Next-Level Large-Format Fiber Laser Machines

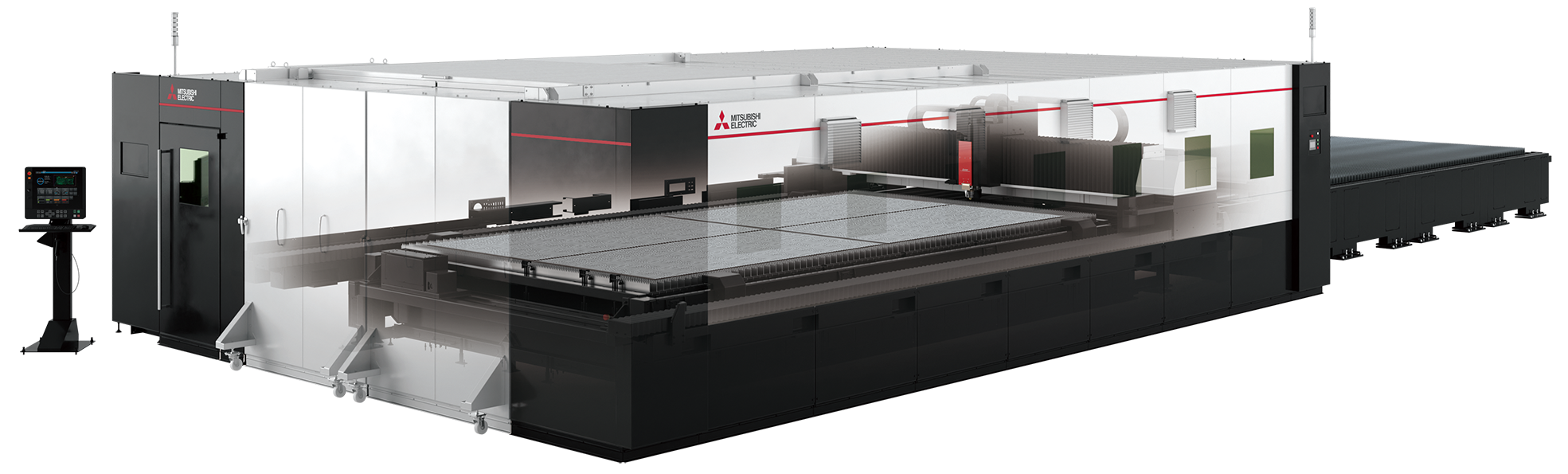

The GXL-F builds upon the solid foundation of its XL-F predecessor with the addition of innovative features inspired by the GX-F ADVANCED Series. With the ability to process four 5’x10’ sheets on one pallet supported by a bed size of up to 10’ x 26’, the GXL-F machine offers maximum versatility.

Packed with industry leading technology such as AI Process Monitoring, AI Nozzle Monitoring, Advanced Gas Reduction and the most cutting edge nozzle technology on the market, the GXL-F is designed to meet the needs of the most demanding users in today’s 24/7 competitive manufacturing environment where performance, precision, flexibility and efficiency are key to staying competitive.

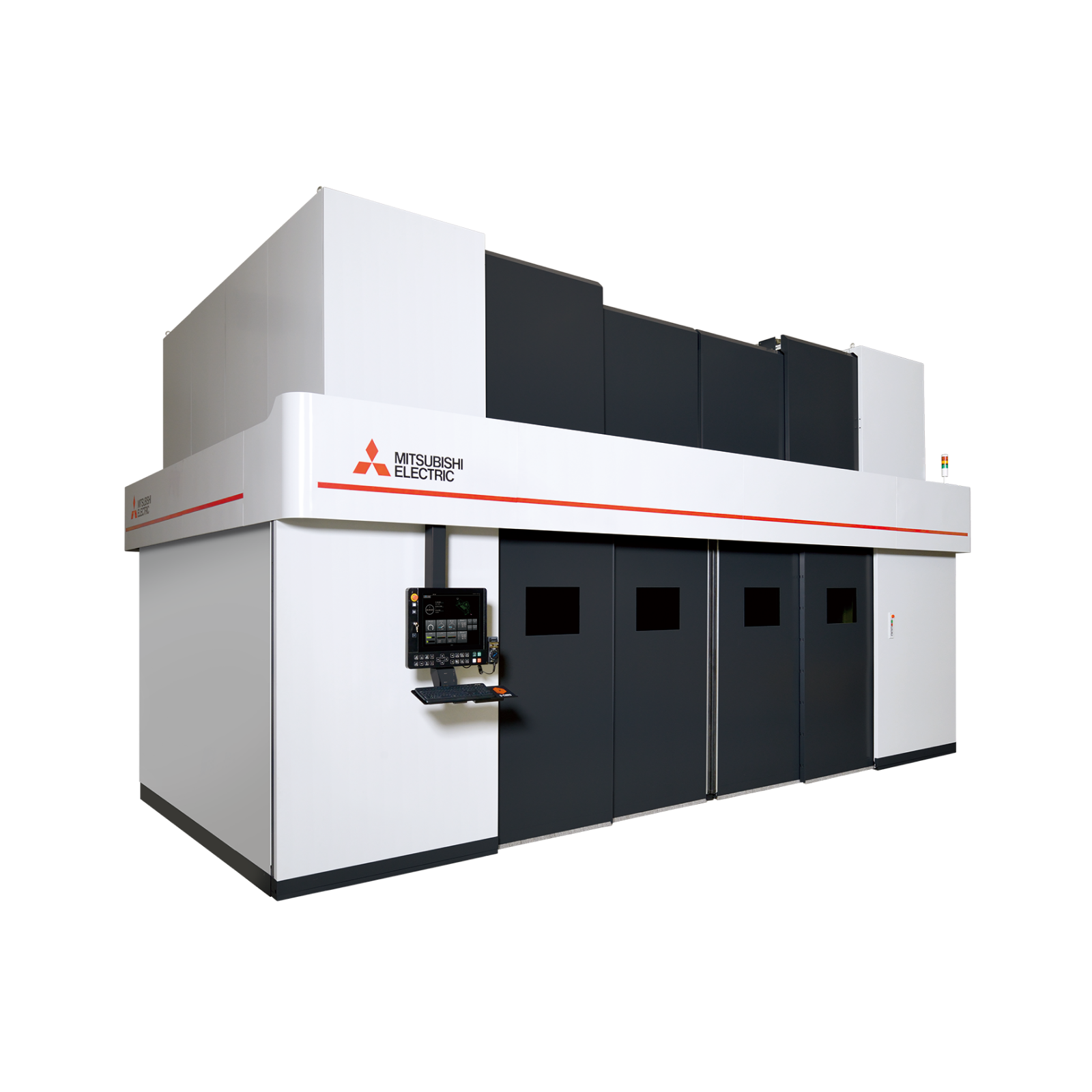

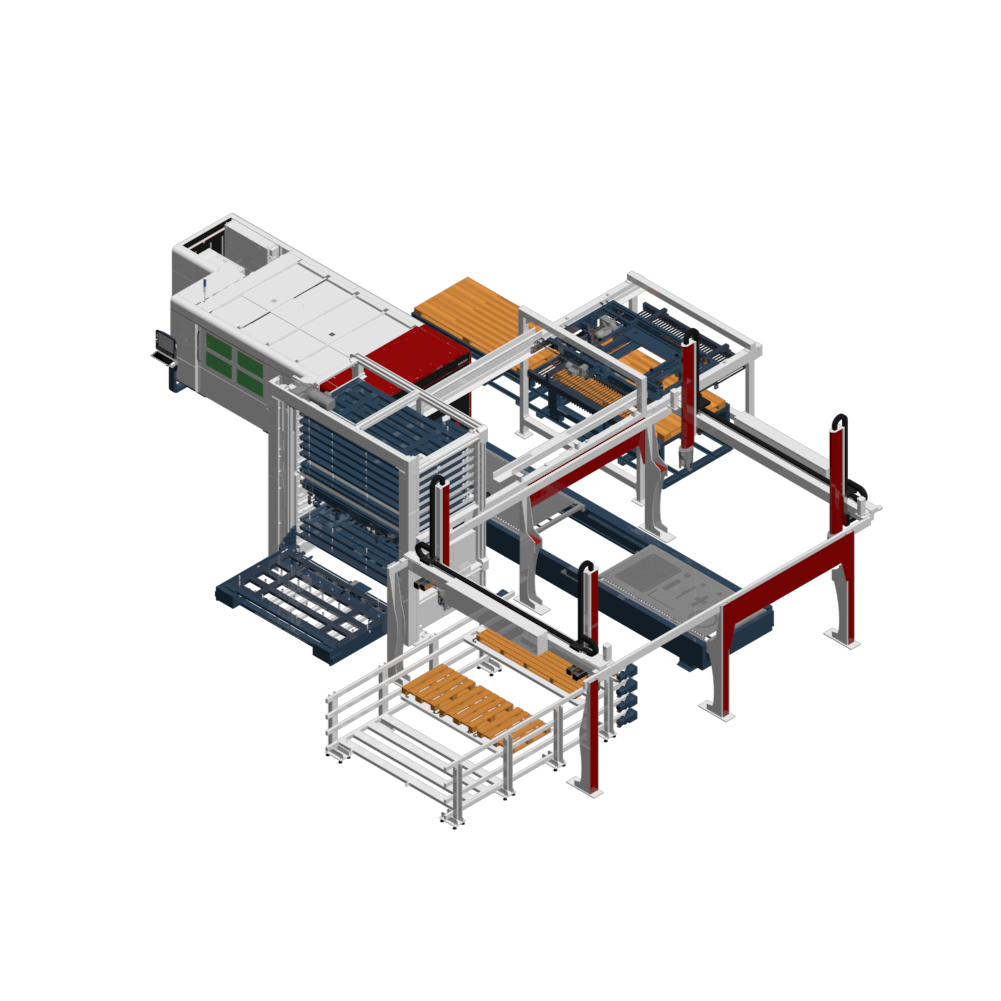

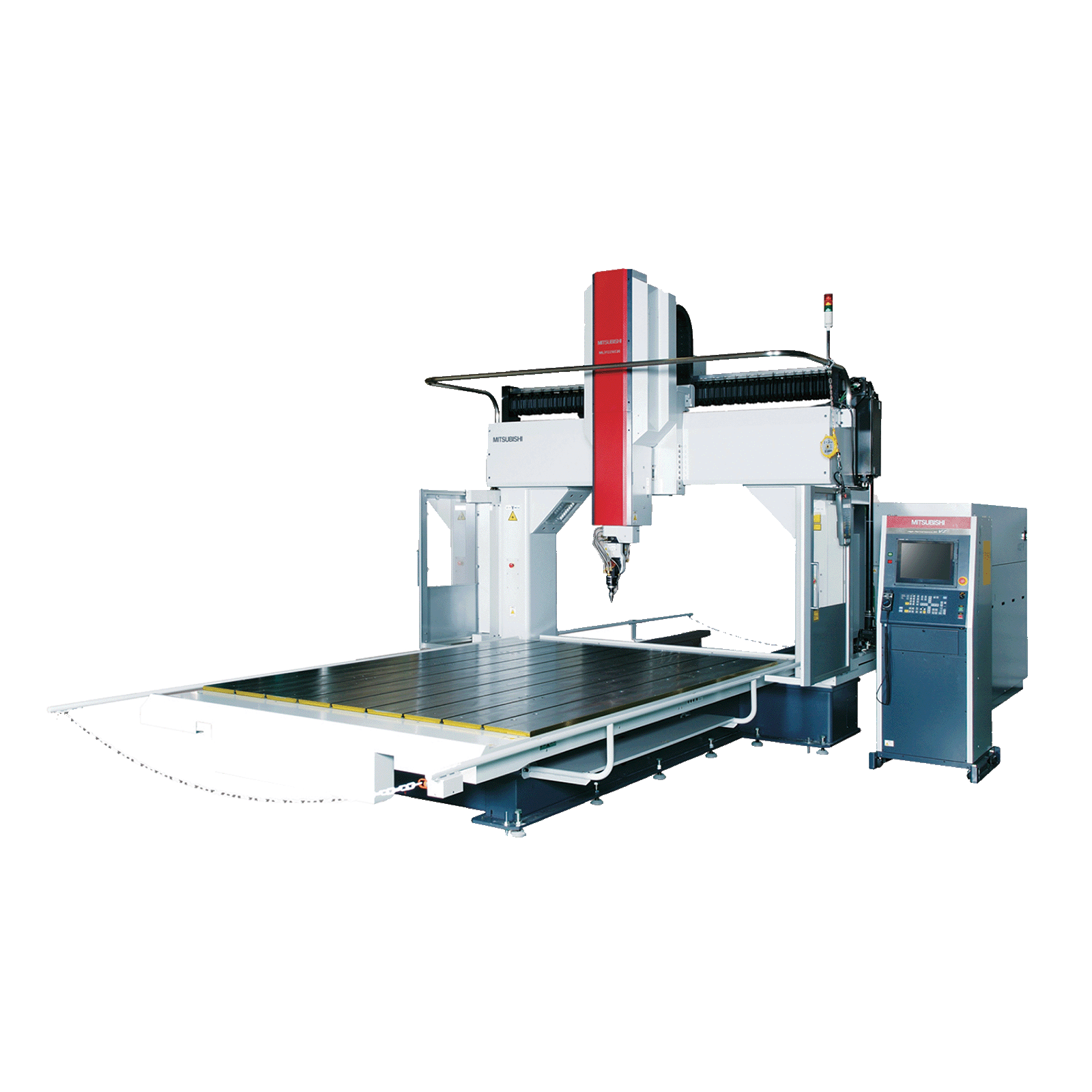

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.