M800 Series CNC Control

Keep your day-to-day operations running smoothly with relevant machine insights.

With a new navigation interface that provides smooth and easy job operation time for operators of any expertise level, the new M800 series CNC control puts a serious competitive advantage for your business firmly within reach.

- Complete production jobs quickly and accurately

- Analyze machine profitability at a glance or over time

- Optimize production processes for maximum efficiency—according to your needs

- View material and resource consumption statuses

- More effectively predict and adapt to potential downtime

- Ensure transparency in all production stages

EASY TO LEARN

The new Advance Pendant Box uses a thin tapered design with a 3.5” LCD touchscreen interface to provide the operator with a greater depth of functionality. This helps shave considerable time off of setup and day-to-day operation alike.

EASY TO USE

New software functions help operators with a setup checklist and enhanced maintenance screens to keep track of operations. All-new common shape macros reduce programming time by as much as 88%.

EASY ON YOUR STAFF

The M800 series CNC control takes design cues from consumer electronic devices to keep users productive and comfortable, day in and day out.

The large 19” touchscreen provides an easy, intuitive interface—housed on an ergonomic tilt/swivel mounting system—that allows users to swipe, pinch, and tap to view important job information in a single view.

The M800 series CNC control is available on these machines, with more on the way soon!

RELATED SOLUTIONS

-

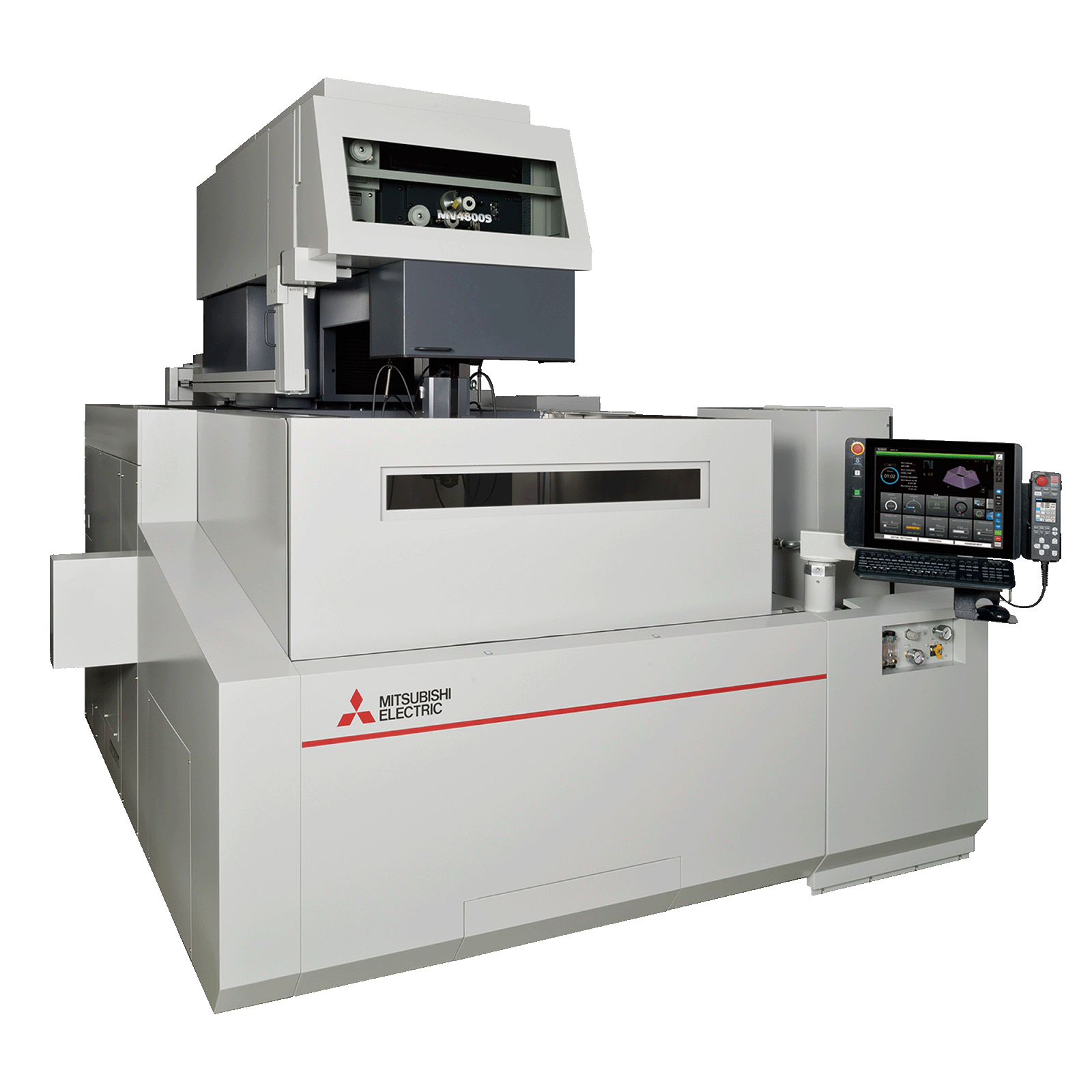

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

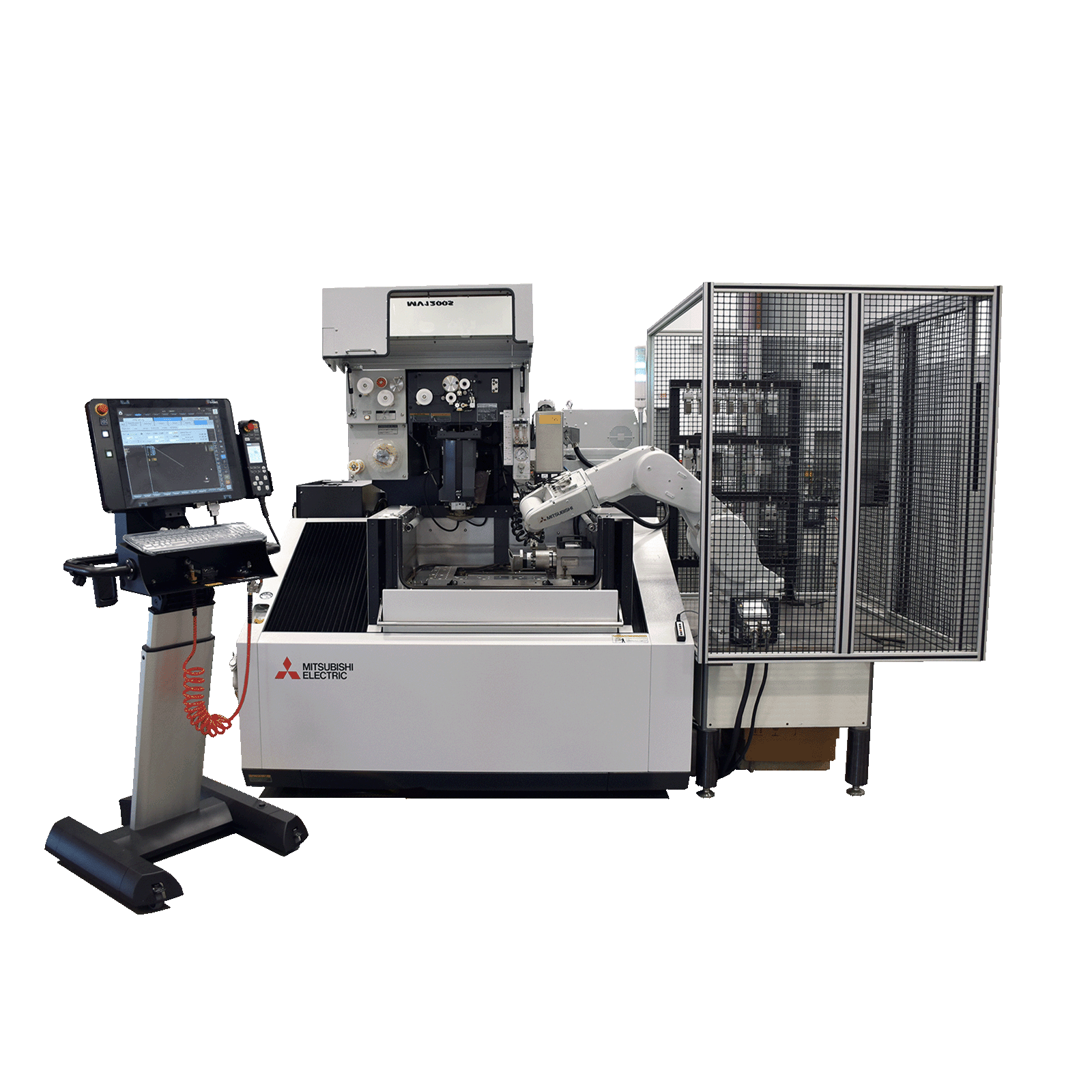

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study -

"Tooling for high-speed stamping has some tight tolerances, but the Mitsubishi wire EDMs have no problems meeting those tolerances. To know what we’re getting out of those machines on a consistent basis is huge for us."

Keith Dombrowski, Dies Plus Wire EDM Supervisor Read case study