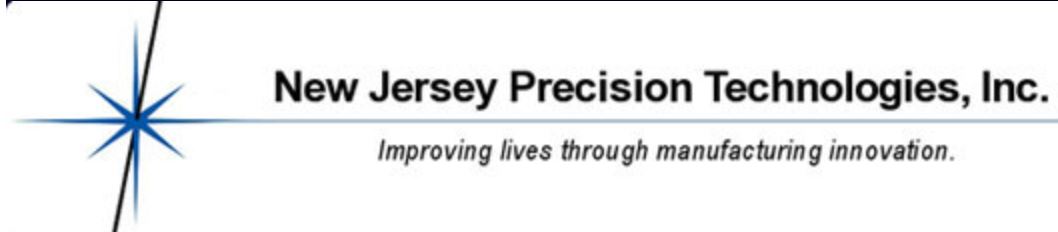

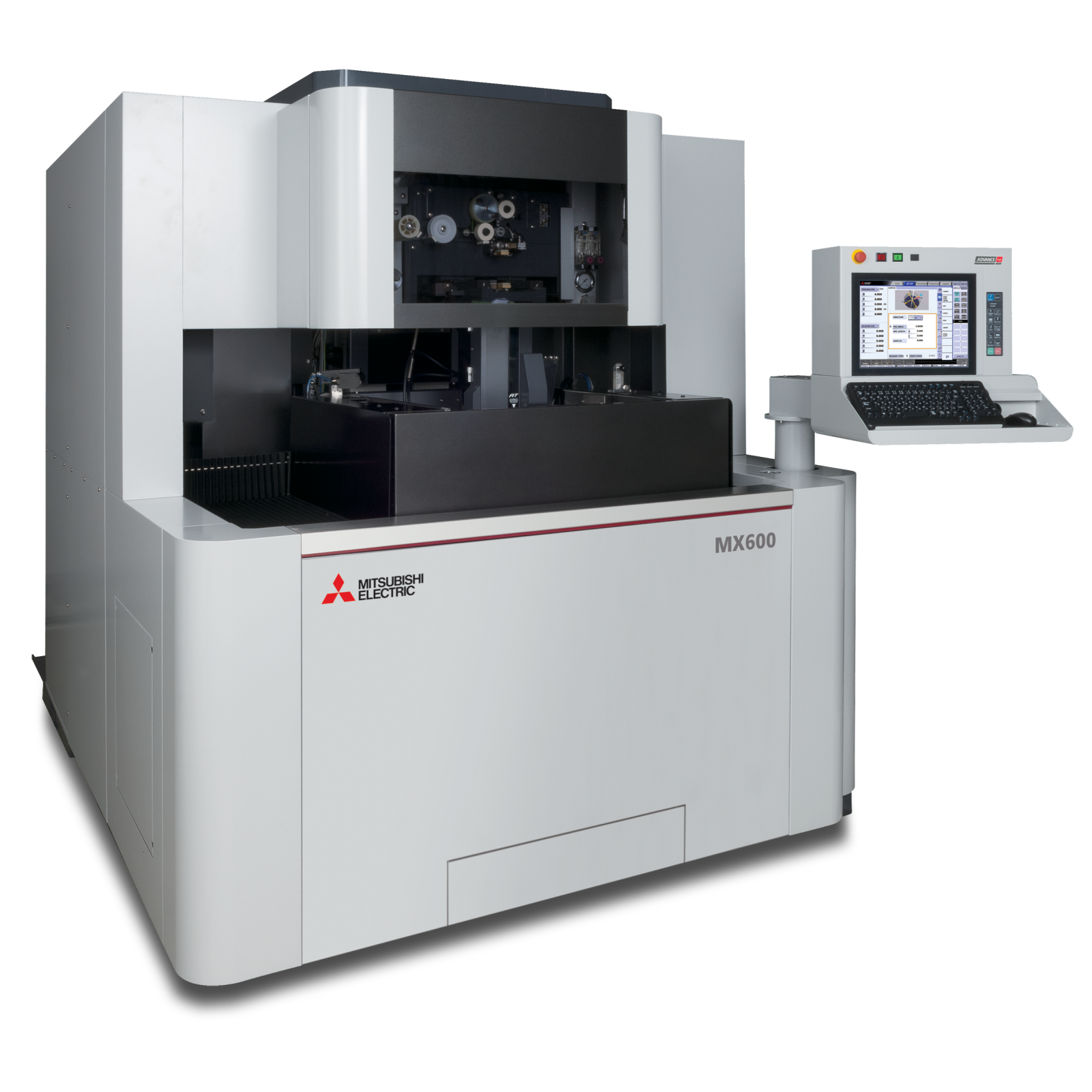

MX600 Advance Plus Wire EDM

Combines the ultimate in machine accuracy and surface finish – Wire capability down to .0008″ (.02mm) Dia.

The ultimate in ultra-fine, ultra-accurate, and ultra-efficient machining, the MX600 Advance Plus is a powerful, versatile oil wire-cut EDM machine with a small footprint that makes it the perfect addition to your factory floor. Featuring an impressive range of new improvements, this machine provides a reliable option for advancing your micro-fine machining capabilities.

The MX600 Advance Plus combines new advances in machine construction, thermal stabilization, ultra-fine wire auto-threading, internal machine communication, and oil-type power supply technology to help manage operating costs while producing top-quality results.

BUILT FOR QUALITY

- Mounting the table to a granite base electrically isolates the workpiece, reducing floating capacitance while providing improved cutting speed and ultra-fine surface finishes.

- The Nano-FS finishing circuit can provide surface finishes as low as 1.4µ”Ra across the entire worktable surface. No special tooling is required.

- Achieves auto-threading down to 0.0008” wire (option)

IMPROVES THROUGHPUT

- An oil dielectric fluid is used to eliminate cobalt depletion in carbide machining and oxidation or rust in iron-base material machining.

- Linear-motion guideways with extra-long linear guide bearings minimize guide waving.

DURABLE, COST-EFFECTIVE MACHINING

- The Mitsubishi nPV (Nano-Pulse) with digital spark control is a dedicated oil-type power supply that integrates the power supply technologies of both water wire EDM and oil sinker EDM, making it specialized for dielectric oil-type machining.

- A mostly enclosed machine cabin protects the machine casting from sudden temperature changes in the environment, and the Thermal Buster System synchronizes the machine working area with the casting using a chilled fluid circulation system.

- DMX-S (Digital Matrix Sensor) shapes each spark, reducing electrode wear.

CAPABILITIES:

- Fully fiber optic servo control allows 4x faster internal communication speeds

- Submerged oil machining up to a 3.9” thick workpiece

- Standard wire size range: 0.0015”~0.008”

- Auto-threading down to 0.02mm (0.0008”) wire diameter (option)

- New 14” auto-threading annealing length improves threading reliability

COMPONENTS:

- Fine-grain, “ductile” cast iron base material

- Single-piece, hardened, 4-sided stainless worktable

- Split-axis construction (table moves in X axis, column moves in Y axis)

- Optical rotary encoder feedback (Z axis)

- Non-contact, zero-backlash linear shaft drive system (X, Y, U, V axis)

- Linear glass scale feedback (X, Y, U, V axis)

- DC-servo (closed loop) torque-control wire-tensioning system

- Dielectric fluid chiller standard

ON-BOARD AUTOMATION:

- Automatic fluid level control

- Automatic vertical machine tank door

- All-axes absolute control system

- Auto-oiler lubrication system

USER INTERFACE:

- Program input methods:

- Keyboard

- USB flash memory

- Ethernet with FTP standard

SYSTEM INFORMATION:

- Windows-embedded operating system

- 80GB hard drive memory with 1GB user program storage

- Fully automatic rough machining control covers PM, CM-R, and EM functions

- Inverter-controlled 16-step programmable flushing

ADDITIONAL BENEFITS:

- Full 2-year warranty with Triple Diamond Partnership Program

- Cylindrical drive system is covered by a special 10-year positioning warranty

- remote360-enabled (remote user monitoring, diagnostics, service support, and more)

- Comes with one complimentary preventative maintenance visit—to be used by the end of 1styear

| Machine Travels: X x Y x Z in (mm) | 11.8 x 7.8 x 7.0 (300 x 200 x 180) |

|---|---|

| Maximum Workpiece Dimensions: W x D x H in (mm) | 24.4 x 24.0 x 3.9 (620 x 610 x 100) |

| Max. Submerged Workpiece Weight: lb. (kg) | 660 (300) |

| Table Dimensions: in (mm) | 22.0 x 19.0 (560 x 485) 4-sided |

| U/V Travels (from center): in (mm) | ±1.4 x ±1.4 (±35 x ±35) |

| Taper Angle @ Thickness: in (mm) | 15 deg.@ 4.0 (15 deg.@ 100) |

| Table Rapid Feed Speed: in/min (mm/min) | 51.2 (1300) |

| Power Supply | nPV (Nano Pulse “V” for oil) |

| Minimum Drive Unit / Resolution | 0.000002 / 2 µin ( 0.00005 / 50nm) |

| User Program Storage [Hard Disk Size] | 1GB [80GB Hard Drive] |

| Wire Diameter Possible: in (mm) | 0.0008~0.008 (0.02~0.2) [.0008 &.0012” Optional] |

| Minimum Start Hole Diameter: in (mm) | 0.002 (0.05) |

| Max. Wire Spool size STD: lb. (kg) | 22 (10) |

| Filters / Type | 2 / Paper |

| Filter Tank Capacity: gal (L) | 80 (300) dielectric oil |

| Machine System Dimensions: in (mm) | 77.6 x 110.2 (1970 x 2800) |

| Machine Installed Height: in (mm) | 82.7 (2100) |

| Machine System Weight: lb. (kg) | 7,495 (3400) |

| Fluid System Weight: lb. (kg) | Included with machine |

| Power Requirements [KVA] | 200-230V [13.5] Built in AVR |

| Compressed Air Requirements | 2.7 cu.ft./min. @ 71~100 psi |

RELATED SOLUTIONS

-

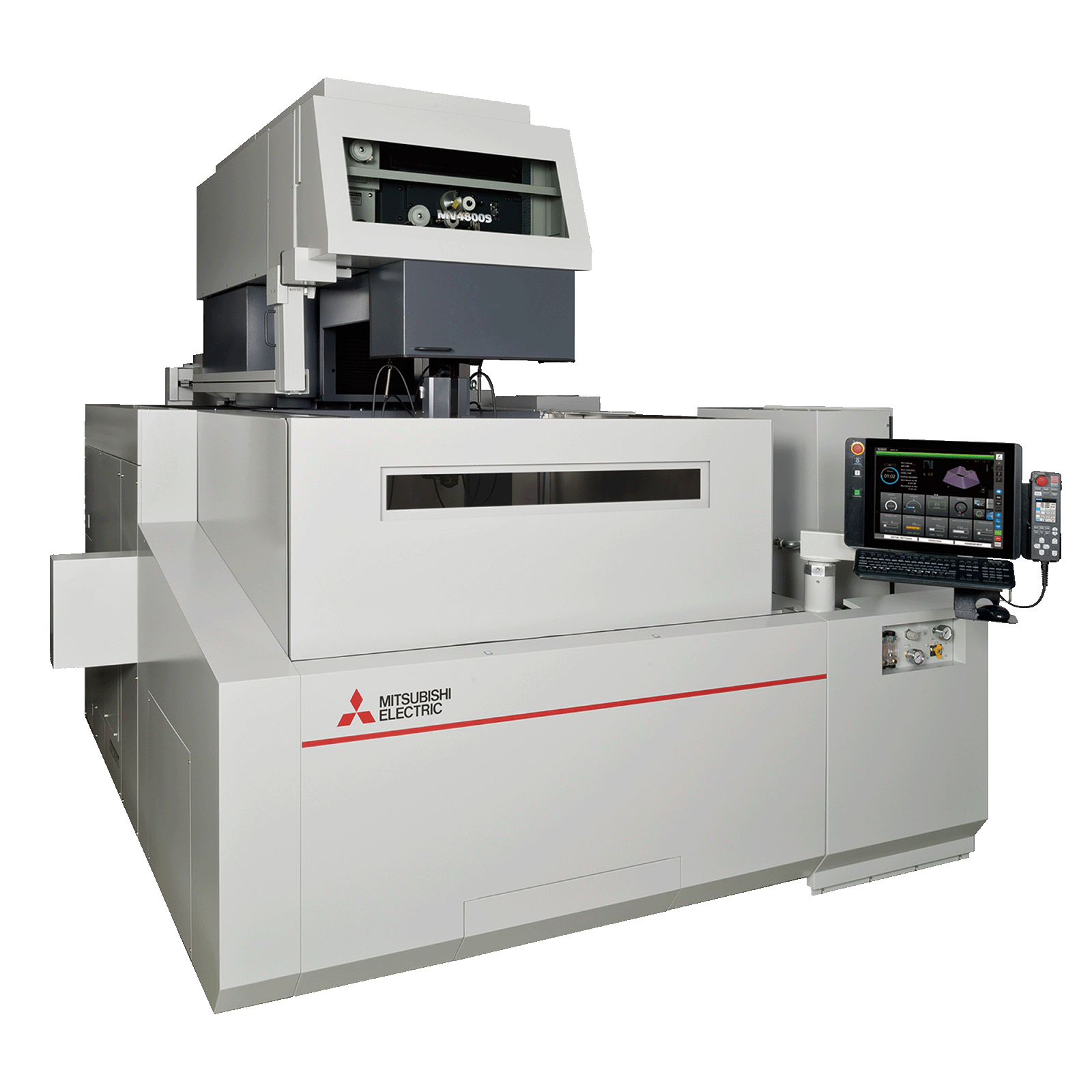

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

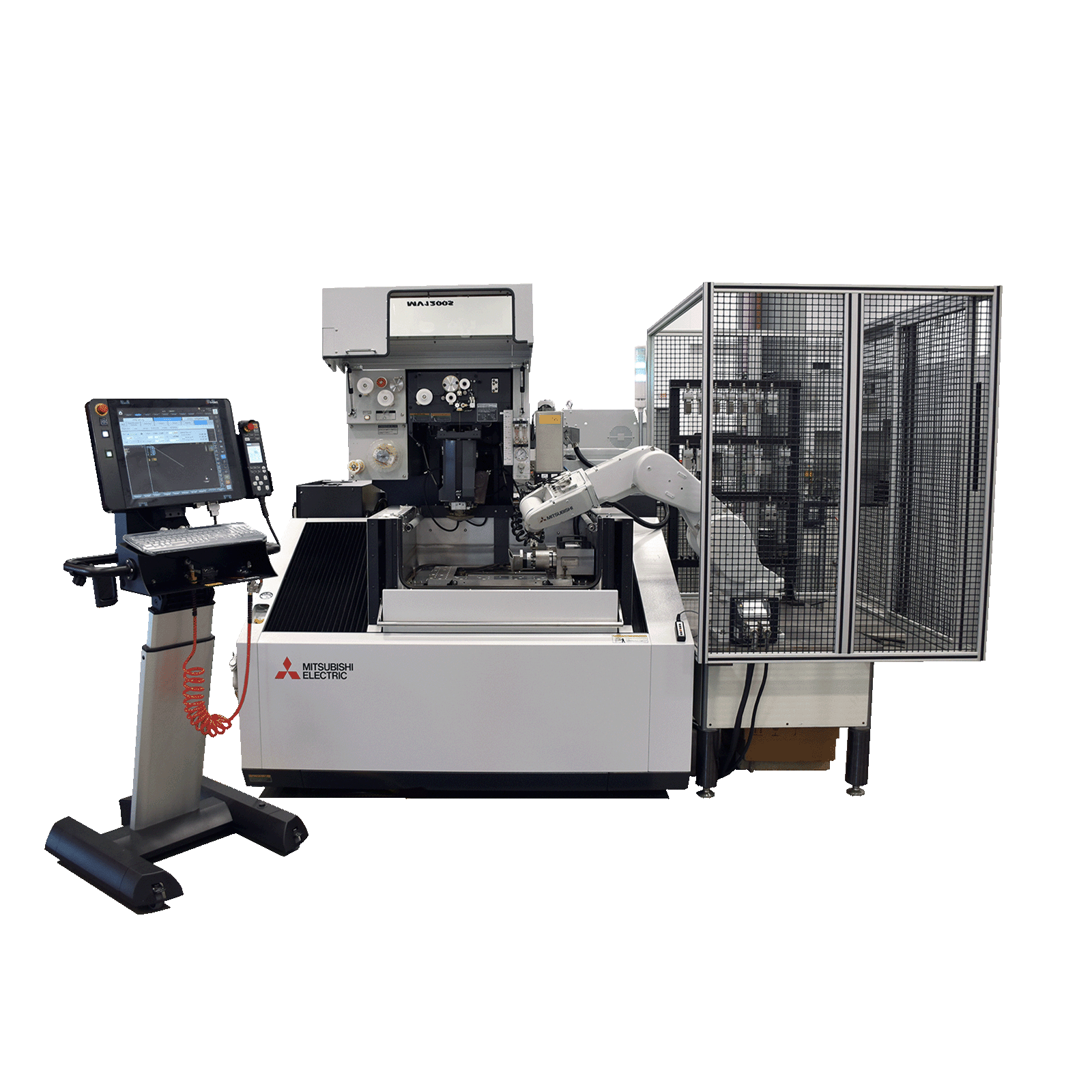

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study -

"Tooling for high-speed stamping has some tight tolerances, but the Mitsubishi wire EDMs have no problems meeting those tolerances. To know what we’re getting out of those machines on a consistent basis is huge for us."

Keith Dombrowski, Dies Plus Wire EDM Supervisor Read case study