SV12P Sinker EDM

An AI-infused powerhouse that brings serious smarts to tight-tolerance machining.

When you’re dealing with tight-tolerance work—especially for mold- and die-making applications—your success always comes down to balancing a few key factors: accuracy, temperature management, and productivity. The SV12P is designed to give you all three at once without compromise. But it also goes several steps further.

This machine delivers the kind of ultra-fine, high-quality work you expect from a sinker EDM, but its ability to machine exotic materials makes it a versatile tool in all kinds of scenarios. Plus, its ergonomic, easy-to-access design and on-board AI and cloud-based monitoring systems make it easy to operate regardless of skill level.

That translates into all kinds of serious benefits for your business, from being more productive while using fewer resources—and spending less money—to creating top-tier work easily and consistently with less maintenance-related downtime.

MANY USES, RELIABLE RESULTS

- The Mitsubishi SV12P with “Thermal Buster” is the ideal choice for tight-tolerance applications such as die and mold, but it can also handle machining for exotic materials. Combined with its compact, easy-to-access design and AI-assisted production, this machine delivers top-tier results in nearly any situation without sacrificing operator usability.

GET SMART ON RESOURCE MANAGEMENT

- The SV12P comes packed with smart machining technologies, all designed to give you an unprecedented level of control over your shop’s finances. With MAISART AI technology and a connection to our cloud-based remote360 machine monitoring, you can improve your productivity by up to 30%, shorten machining time by up to 50%, reduce waste, and protect yourself from costly maintenance and downtime due to electrode wear.

INSIGHTFUL, EASY-TO-USE CNC CONTROL

- This machine comes with the M800 series control, granting you and your team easy access to a wealth of useful data and hidden insights. The 19” touchscreen enables the user to swipe, pinch, and tap to view, making it an easy way to increase productivity and help keep track of production jobs.

CAPABILITIES:

- The on-board MAISART AI intelligence is designed to work in unison with the IDPM3, which can reduce wear in graphite electrodes by up to80% while cutting machining time in half.

- The HPS circuit enhances machining speed while reducing electrode wear, even while working with exotic materials such as PCD, cBN,or carbide.

- Our new Thermal Buster thermal displacement compensation system and Z axis cooling mechanism improves accuracy by tracking and compensating for machine temperature changes .

- The standard NP2 circuit provides an ultra-fine, satin surface finish anywhere on the table surface.

- An enhanced LLTX “Lotus Leaf Texture”circuit for glossy mirror finishing improves mold releasability without the need for polishing .

- The GV80P energy-saving power supply reduces electrical consumption by 20% compared to the previous FP model.

- ESPER II Navigator provides advance program support functions, giving operators unprecedented control over machine operation.

- The advanced pendant control uses an all-new 3.5” thin crystal LCD,providing automatic alignment and pickup routines (built into the control),and “walk around” portability significantly reduces workpiece setup time.

- Sided worktank is accessible from all 3sides, making operation and maintenance quick and painless .

- Capable of high-speed rapid travel at up to 275”/min. (7m/min.).

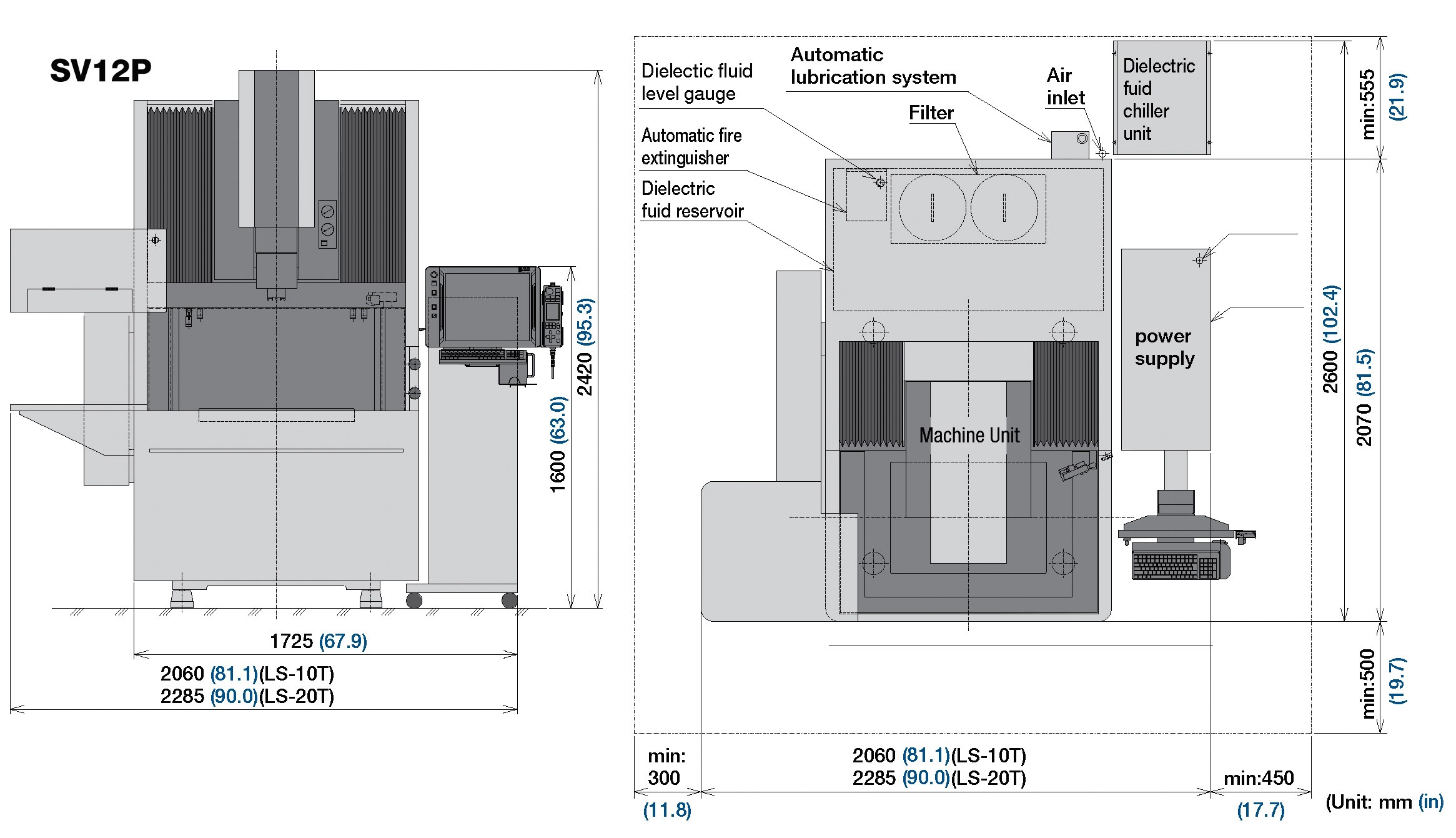

COMPONENTS:

- SS Jump 5 with 984”/min.(25m/min.) jump speed @ 1.6G acceleration (NO-FLUSH machining).

- GV80P power supply provides 80 peak AMPs (GV120P –120AMP option).

- Compact yet highly rigid machine design.

- Fixed table traveling column construction.

- Direct drive AC smart servo system.

- 3Dlateral servo system.

- Thermal Buster thermal displacement compensation system.

- LLTX “Lotus Leaf TeXture” system for glossy mirror finishing.

- NP2 circuit standard (0.05μm Ra)for ultra-fine matte finishing.

- Superlow-wear SC circuit.

- Fine matte finish PS circuit.

- Narrow gap circuit.

- Easy-access filter system with two filter elements.

- Dielectric fluid emission.

- Dielectric fluid chiller standard.

ON-BOARD AUTOMATION:

- Automatic lubrication system.

USER INTERFACE:

- M800 seriesCNCcontrol with 19″ ergonomic touchscreen

- Advanced pendant control with 3.5” LCD screen with multiple menus

- Program input methods:

- Keyboard

- USB flash memory

- Ethernet with FTP standard

SYSTEM INFORMATION:

- IDPM-3 “Intelligent Digital Power Master” adaptive control with MAISART artificial intelligence.

- CFAST compact flash card memory with a 1GB partition for user program storage.

- ESPER Advance Pro-Lite programming.

- On-board anti-virus protection included.

ADDITIONAL BENEFITS:

- Full 2-yearwarranty with Triple Diamond Partnership Program.

- remote360 included at no charge during machine warranty period (remote monitoring, diagnostics, service support and more).

- Comes with one complimentary preventative maintenance visit—to be used by the end of first year.

| Machine Travels X x Y x Z: in (mm) | 15.7 x 11.8 x 11.8 (400 x 300 x 300) |

|---|---|

| Maximum Workpiece Size W x D x H: in (mm) | 35.4 x 25.6 x 13.8 (900 x 650 x 350) |

| Max Dielectric Fluid Level: in (mm) | 2.6 ~ 15.7 (65 ~ 400) |

| Power Supply (Option) / Peak Current | GV80P / 80 AMPs (GV120P / 120 AMPs) |

| Internal Worktank Dimensions W x D x H: in (mm) | 37.4 x 27.5 x 17.7 (950 x 700 x 450) |

| Worktank / Door Type | 3-Sided Drop Tank |

| Max. Workpiece Weight: lb. (kg) | 2,200 (1,000) |

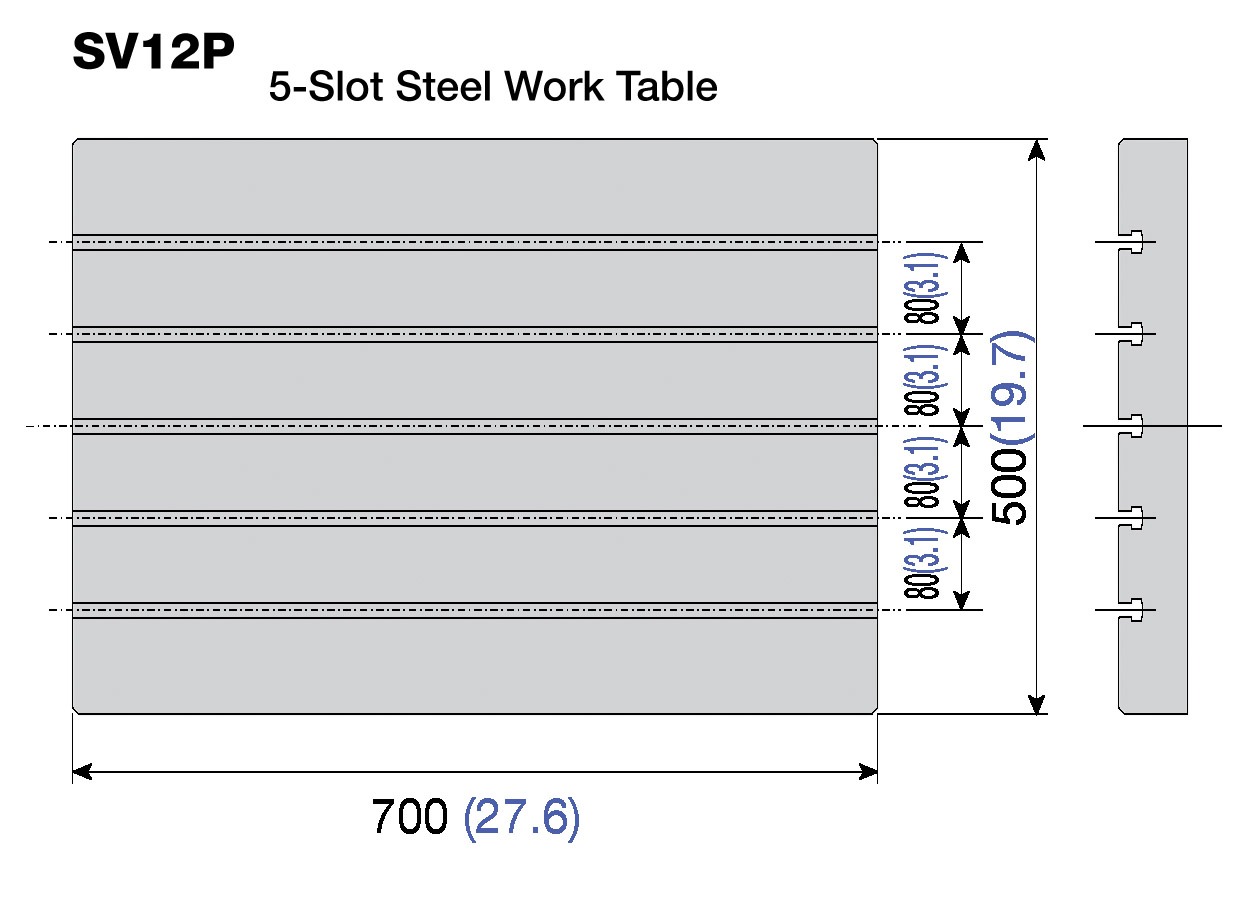

| Table Dimensions W x D: in (mm) | 27.5 x 19.7 (700 x 500) |

| Max. Electrode Weight on Platen: lb. (kg) | 176.5 (80) |

| Table to Platen Distance Min ~ Max: in (mm) | 7.9 ~ 19.7 (200 ~ 500) |

| Table to C-Axis Chuck Distance Min ~ Max: in (mm) | 7.9 ~ 19.7 (200 ~ 500) EROWA ITS Chuck |

| Table to C-Axis Chuck Distance Min ~ Max: in (mm) | 7.2 ~ 19.0 (183 ~ 483) 3R MACRO Chuck |

| Minimum Command Unit / Resolution: in (mm) | .00001 / .000002 (.0001 / .00005) |

| Rapid Travel Speed: in/min. (mm/min.) | 275.5 (7) |

| High-Speed Jump Maximum: in/min. (m/min.)[G] | 984 (25)[1.6] |

| Linear Scale Resolution X, Y, Z-Axis Std.: µm | 0.05 |

| Filters / Type | 2 pc. / Paper Cartridge |

| Filter Tank Capacity: gal (L) | 124 (470) |

| Machine System Dimensions W x D: in (mm) | 110.6 x 122.0 (2,810 x 3,100) |

| Machine Installed Height: in (mm) | 93.7 (2,380) |

| Machine System Weight: lb. (kg) | 7,716 (3,500) |

| C-Axis Min. Indexing Angle / Drive Unit | .001º / .001º |

| C-Axis RPM Range | 1 ~ 30 |

| Fluid Temp. Control | Chiller Standard |

| Optional Internal Spindle RPM Range | 1 ~ 1,500 |

| Automatic Tool Changer Options | MVH-40 |

| Power Requirements [KVA] | 200/220 VAC ±5% [7 w GV80P, 10 w GV120P] |

| Compressed Air Requirements | 2.7 cu.ft./min @ 90-100 psi |

RELATED SOLUTIONS

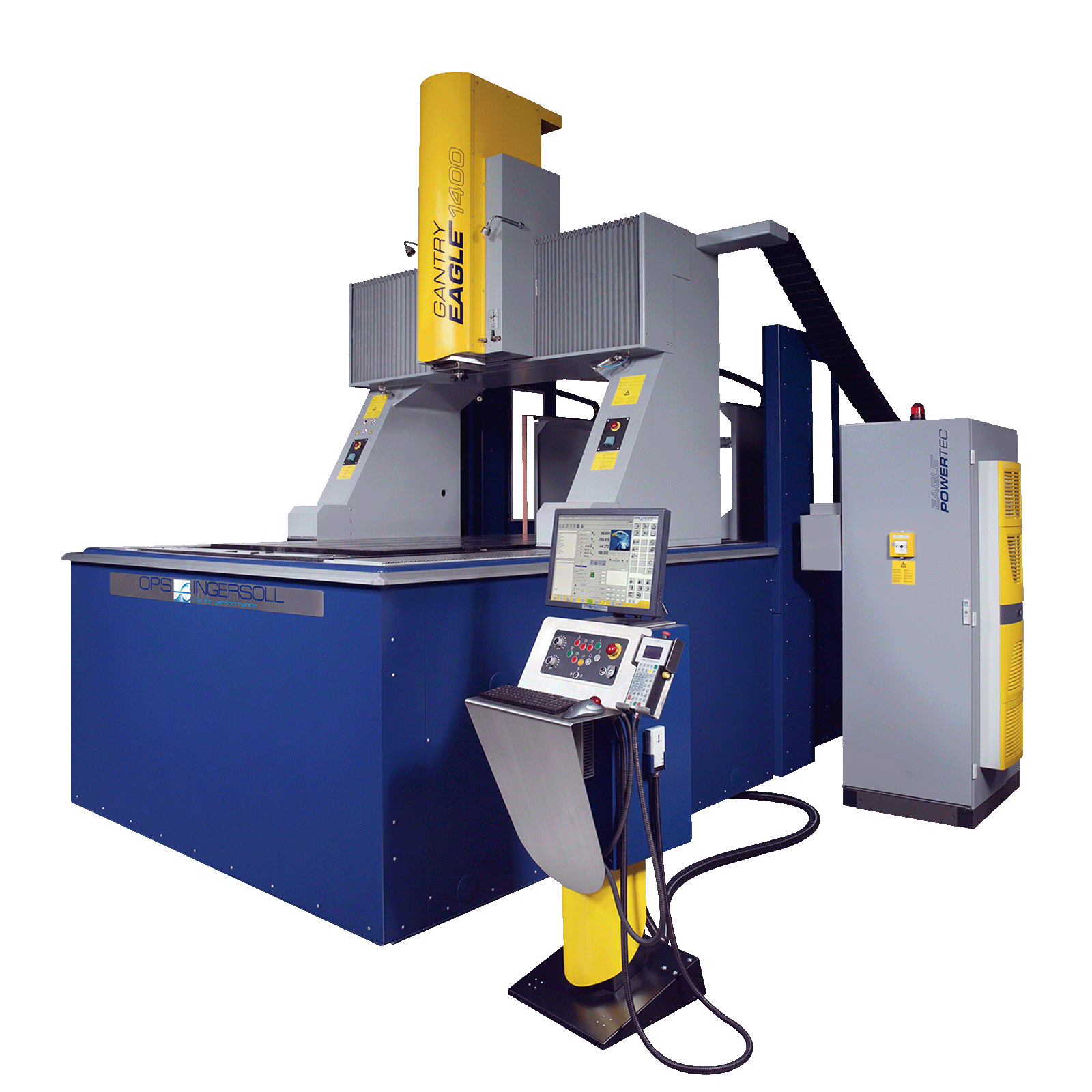

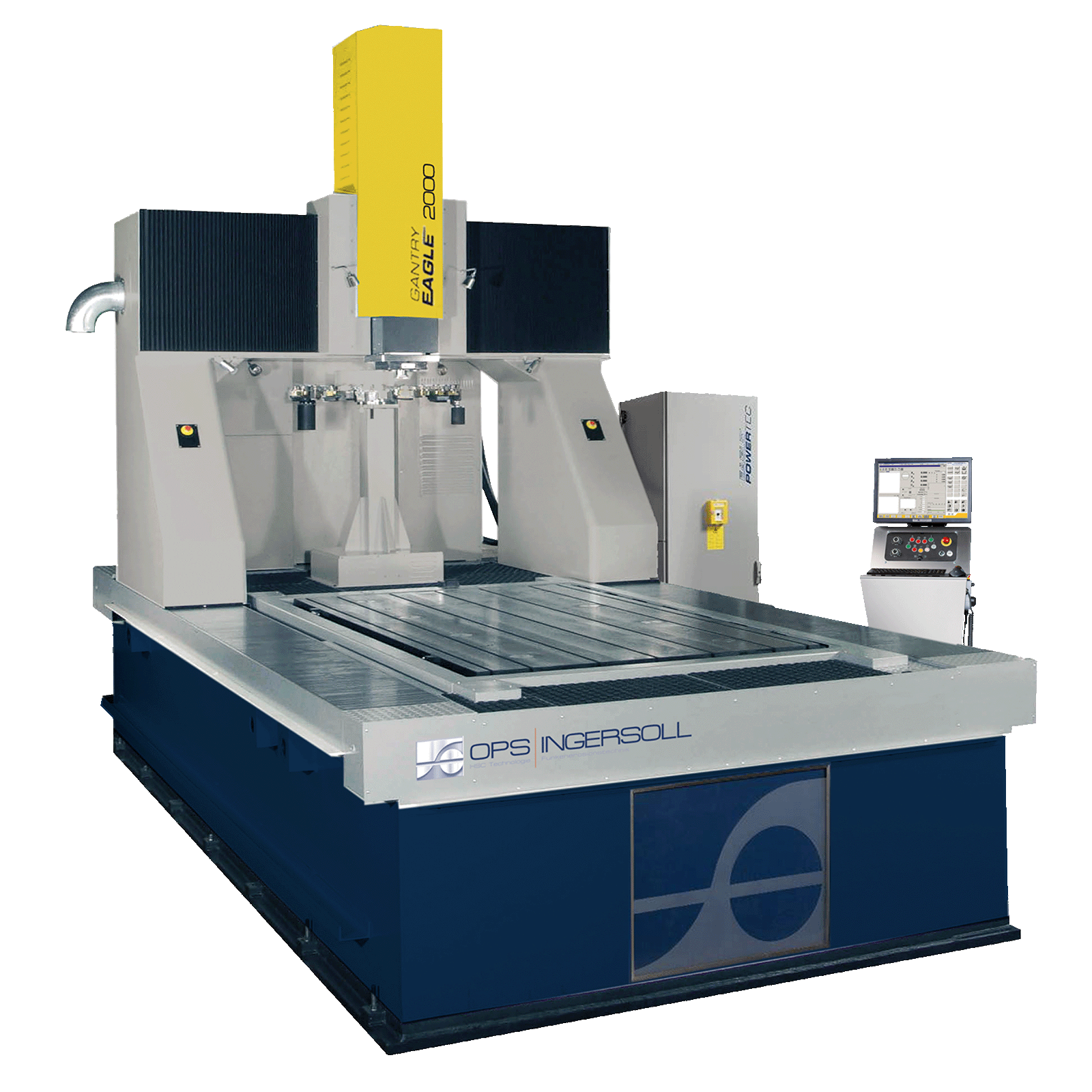

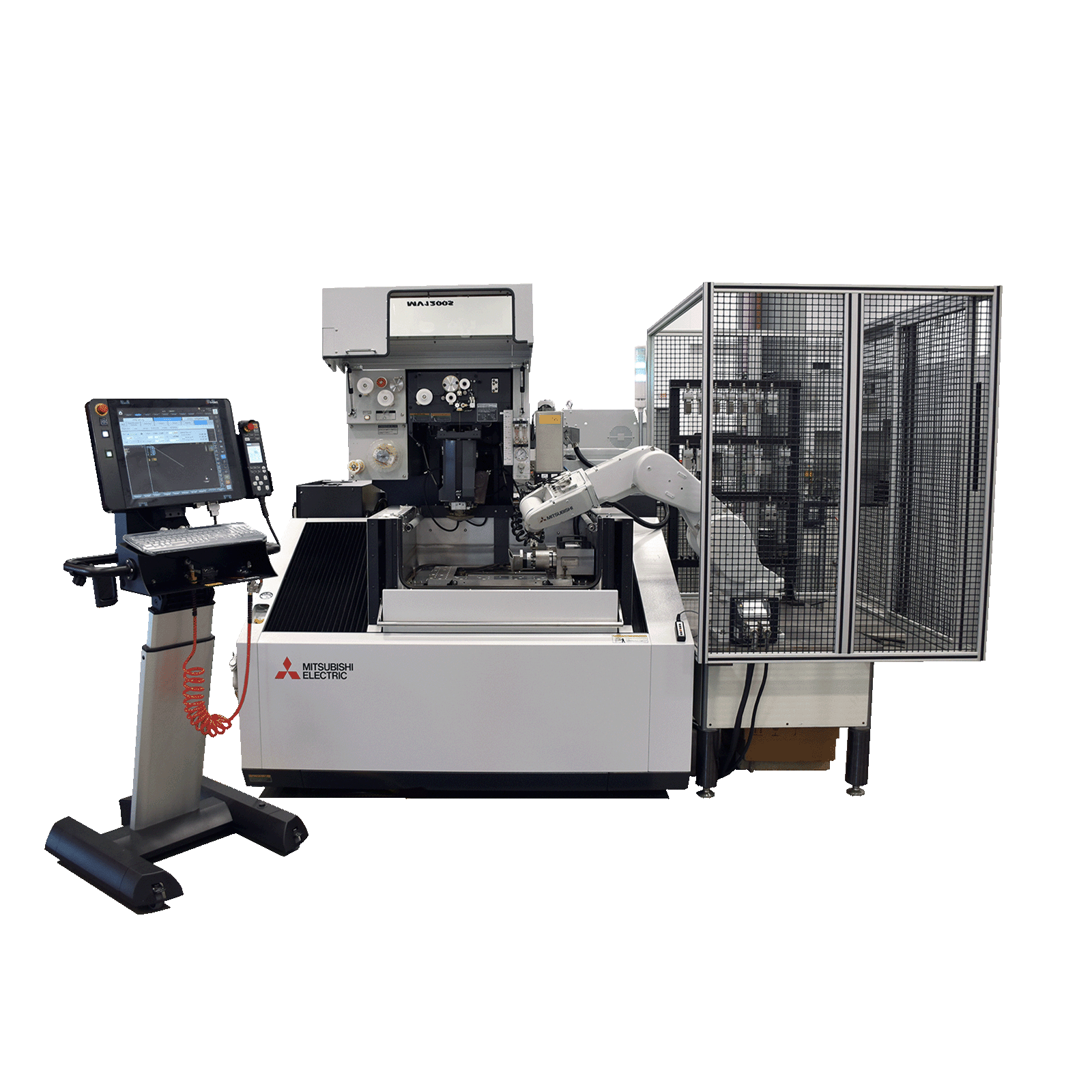

-

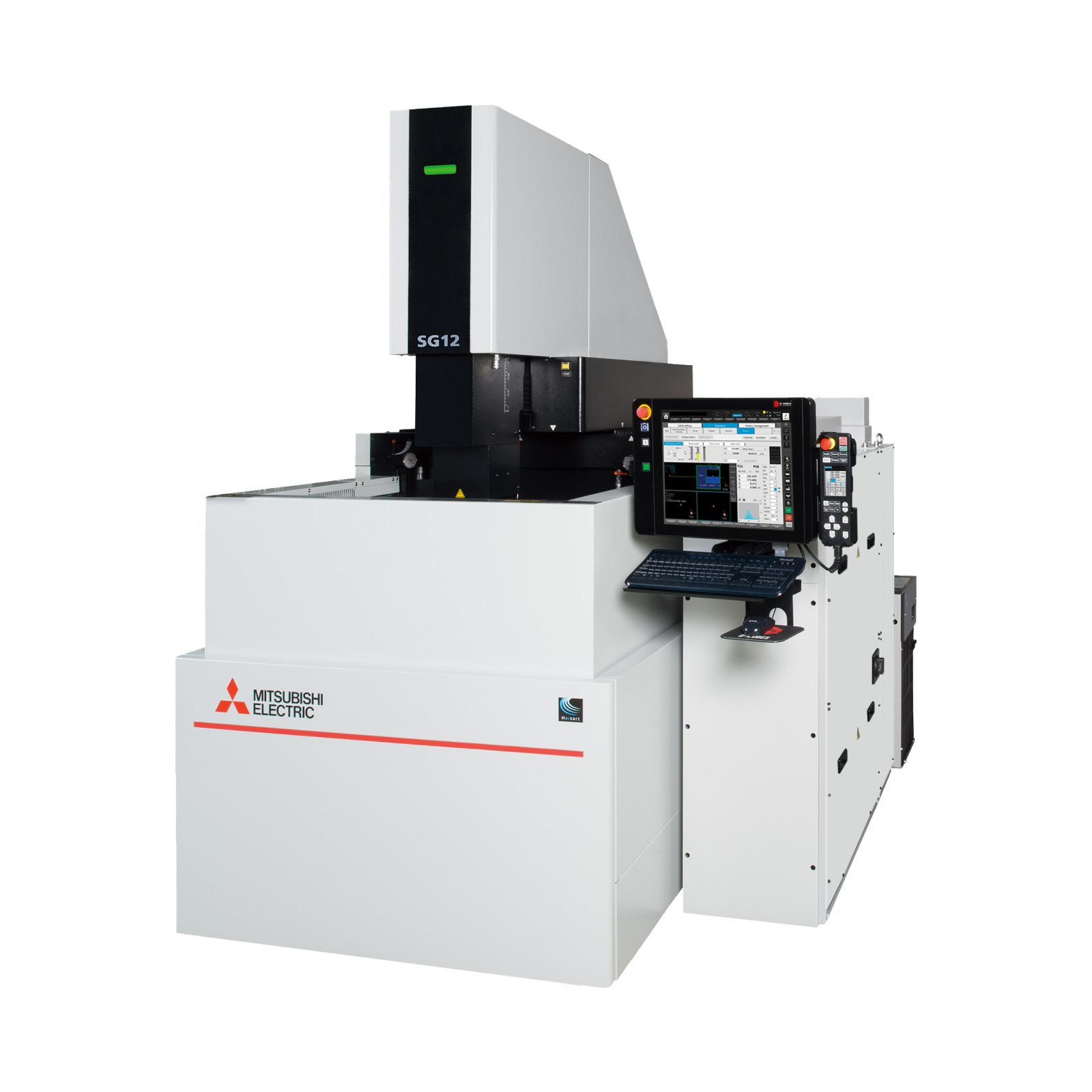

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

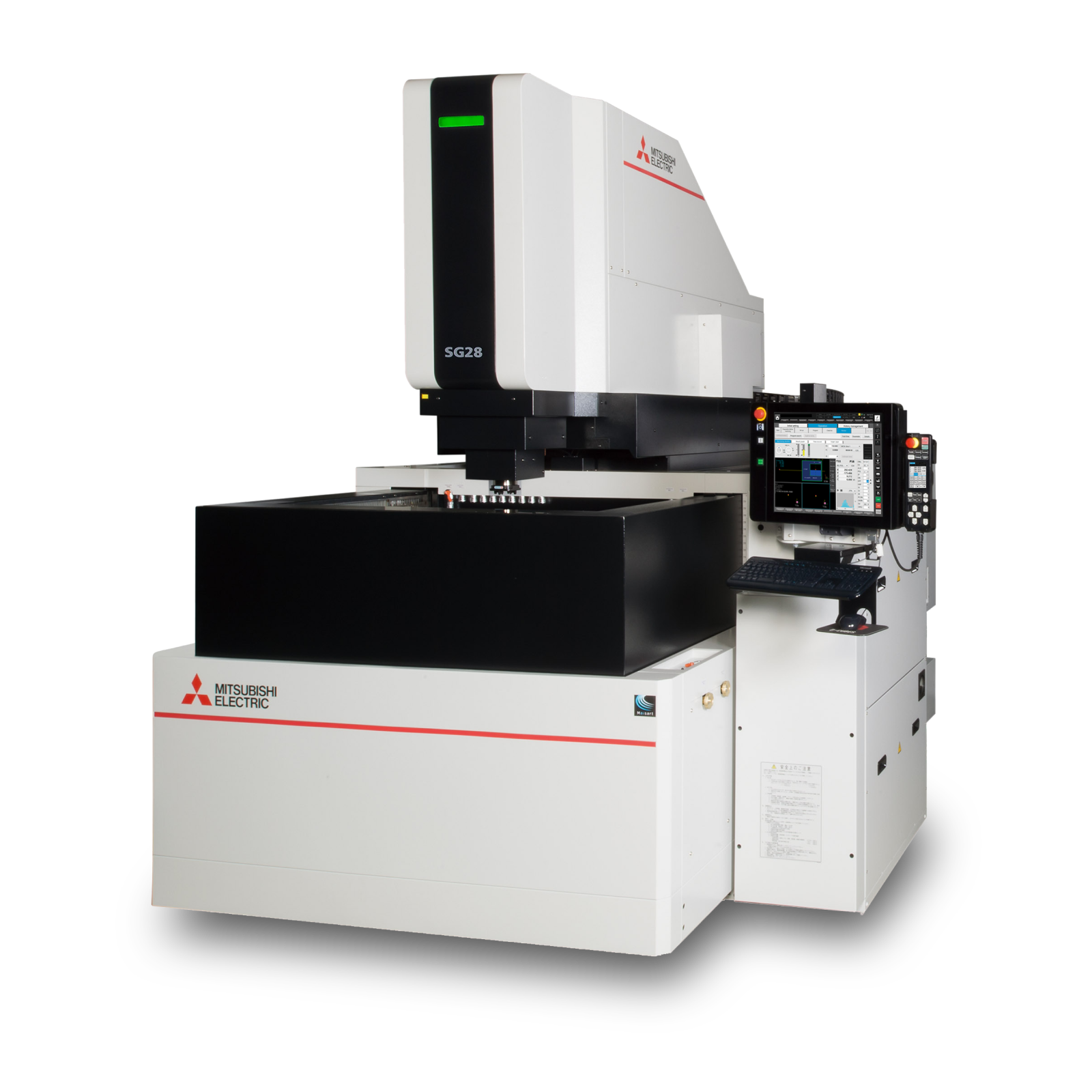

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study -

"Tooling for high-speed stamping has some tight tolerances, but the Mitsubishi wire EDMs have no problems meeting those tolerances. To know what we’re getting out of those machines on a consistent basis is huge for us."

Keith Dombrowski, Dies Plus Wire EDM Supervisor Read case study